| |

TM 10-3930-664-24

B. CLEANING

WARNING

Observe

cleaning

solvent

and

compressed

air

warnings

during

cleaning of cooler core. Refer to

paragraph 1-24.

1. Plug cooler core and soak in cleaning solvent to

remove coolant deposits.

2. Remove plugs and back flush oil passages using

cleaning solvent. Dry using compressed air.

3. Scrape gasket remnants from cooler sealing surface

to ensure proper seal.

4. Clean remaining components in accordance with

paragraph 1-24.

C. INSPECTION

1. Inspect oil cooler components in accordance with

paragraph 1-24.

2. Inspect cooler core joints for corrosion, cracks, or

other damage.

D. TESTING

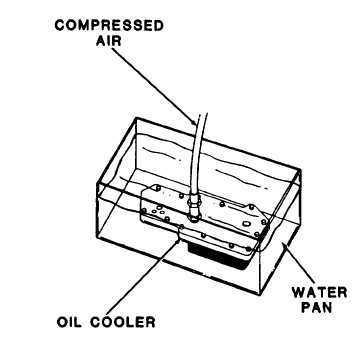

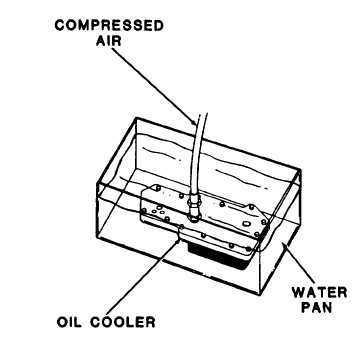

1. Fill water pan with enough water to allow for

submersion of oil cooler.

2. Connect 70 psi (483 kPa) compressed air source to

oil cooler.

3. Apply compressed air and check for air leaks. If air

leaks are discovered, replace defective components.

2-77

|