| |

TM10-3930-660-34

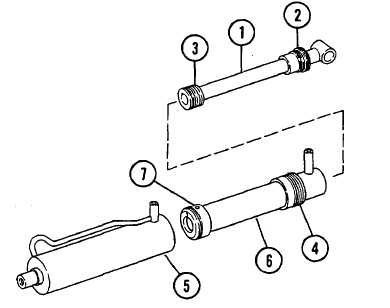

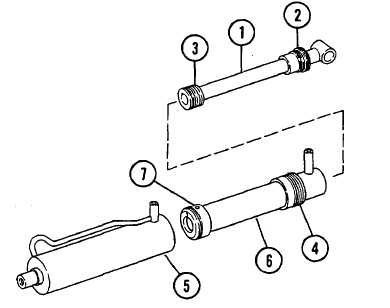

16-17. FORK SIDESHIFT CYLINDERS - REPAIR

This task covers:

a.

Disassembly

b.

Cleaning

c.

Inspection

d.

Assembly

Initial Setup

Tools

Materials/Parts

Tool Kit, Automotive Mechanics

Container

Hydraulic Oil (App. B, Item 35)

Shop Equipment, Automotive

Lint-Free Rags (App. B, Item 38)

Maintenance, Common #2

O-rings (10, 16)

Less Power

Seal (15)

Wrench Set, Spanner, Consisting of

the following:

Spanner Wrench, Frame Tilt Cylinder;

Spanner Wrench, Carriage Tilt and

Attachment Hoist;

Spanner Wrench, Fork Sideshift

Cylinder - Outer Gland;

Spanner Wrench, Fork Sideshift

Cylinder - Outer Piston;

Spanner Wrench, Boom Lift Cylinder

and Boom Extend Cylinder.

Wrench, Strap, 1-6 inch Capacity

Equipment Condition

Fork sideshift cylinder removed,

TM10-3930-660-20.

DISASSEMBLY

1.

USE A VISE WITH SOFT JAWS TO SECURE

CYLINDER IN A HORIZONTAL POSITION

FOR DISASSEMBLY.

2.

DISASSEMBLE CYLINDER PARTS (1-19).

CAUTION

Do not scratch or damage the wear

surface of rod (1), piston or inner

gland (2). Follow this precaution to

prevent failure of the cylinder.

a.

Use a suitable tool to pull rod

(1) out approximately 5 inches

for removal of inner gland (2).

16-107

|