| |

TM10-3930-660-34

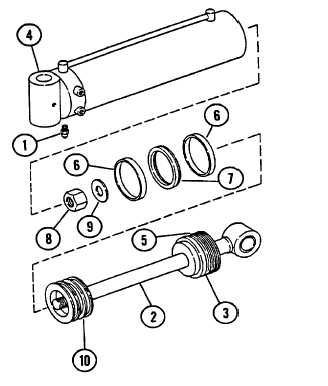

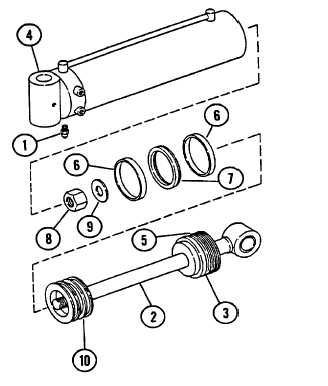

16-10. CARRIAGE TILT CYLINDER - REPAIR (Cont’d)

ASSEMBLY

NOTE

Wipe all sealing surfaces on cylinder

clean and dry. Apply film of clean

hydraulic oil to all seals as they are

installed.

1.

ASSEMBLE CYLINDER PARTS (1-16).

a.

Install bushing (16).

b.

Install seal (14) and rod wiper (15) inside gland

(3).Ensure that seal (14) lip is positioned the

same way as it was before disassembly.

c.

Install back-up ring (13) and new O-ring (5) on

outside diameter of gland (3).

d.

Slide gland (3) and washer (12) onto rod (2).

e.

Lubricate piston (10) inner diameter with clean

hydraulic oil. Install new O-ring (11) inside bore

of piston (10).

f.

Use cleaning solvent and lint free rag to clean

threads on rod (2) and new nut (8).

g.

Slide piston (10) onto rod (2).

h. Apply Loctite 1271 on threads of rod (2) and nut

(8).Install nut (8) and washer (9) on rod (2).

i. Place rod (2) and piston assembly on suitable

supports to prevent damage during assembly.

j. Install two wear rings (6) and one new seal (7) on

piston (10). Position wear rings so that gaps are

180 degrees apart.

CAUTION

Use care when installing rod (2) and

piston assembly. Keep rod (2) in line

with cylinder tube (4) to prevent binding.

Failure to follow this precaution will

cause part damage.

k.

Lubricate cylinder tube (4) inner diameter, piston

(10) outside diameter and gland (3) outside

diameter with clean hydraulic oil.

1.

Position rod (2) and piston assembly in cylinder tube

(4).

NOTE

Tighten gland (3) so that it is flush with

end

of

cylinder

tube

(4).Do

not

overtighten gland.

m. Tighten gland (3) onto cylinder tube (4).

n.

Install counterbalance valve (1) in cylinder tube

(4) as noted during disassembly.

2.

INSTALL CARRIAGE TILT CYLINDER, TM10-3930-

660-20.

16-44

|