| |

TM10-3930-660-34

16-3. TANDEM GEAR PUMP - REPAIR (Cont’d)

CAUTION

If parts are difficult to fit during assembly, tap with a soft

hammer. Use care to prevent part damage.

c.

Ensure that dowel pins (20) are in place. Install

bearing carrier (18) onto gear housing (21). Align

dowel holes over dowel pins (20). Use a soft

hammer to tap parts together.

d. Install connecting shaft (22) in spline of drive gear (27).

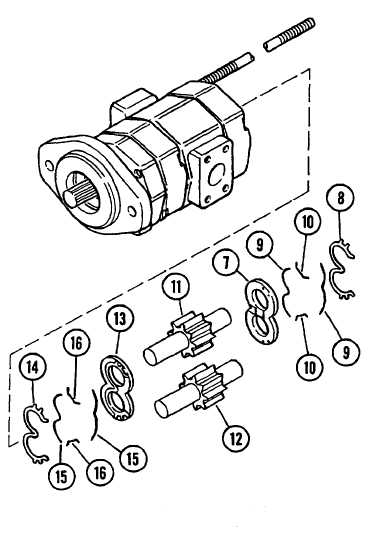

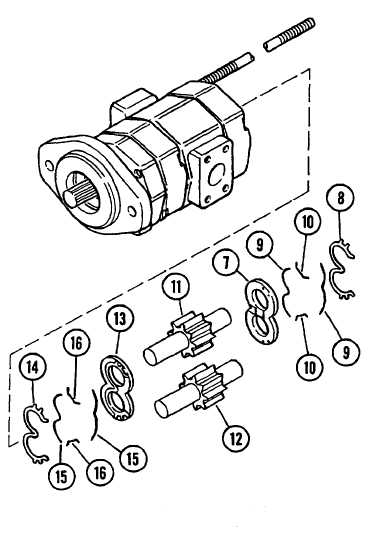

4. INSTALL GEAR HOUSING (6) AND OTHER PARTS (7-

16, 19).

a.

Apply grease on two new seals (19). Install seals

(19) into grooves on gear housing (6).

CAUTION

If parts are difficult to fit during assembly, tap

with a soft hammer. Use care to prevent part

damage.

b.

Ensure that dowel pins (17) are in place. Install

gear housing (6) onto bearing carrier (18). Align

dowel holes over dowel pins (17). Use a soft

hammer to tap parts together. Use care to prevent

damage to seals (31).

c.

Install new seals (14), (15), and (16) into grooves in

thrust plate (13) with flat side of seal (14) facing

away from thrust plate.

d.

Install drive gear (11) driven gear (12) into bearing

carrier (15). Ensure that gears are in contact with

thrust plate (13) face.

e.

Install new seals (8), (9), and (10) into grooves in thrust plate (7) with flat side of seal facing away from thrust

plate.

f.

Install thrust plate (7) with seals over gears (11 and 12). The flat side of seal (8) should be facing up with relief

groove facing outlet side.

16-17

|