| |

TM 10-3930-660-34

9-5 . BEAR DIFFERENTIAL CARRIER ASSEMBLY - REPLACE/REPAIR/ADJUST (Cont’d)

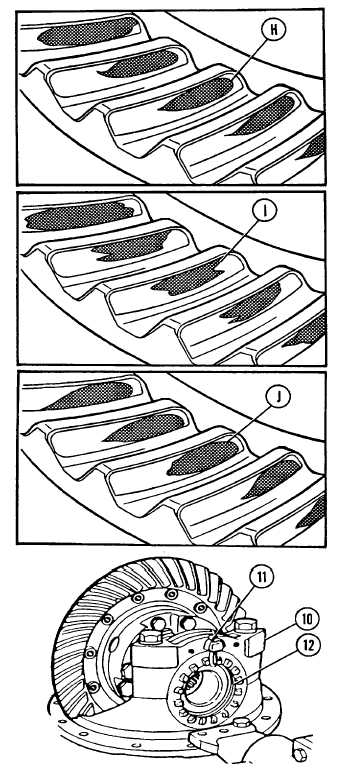

a.

Apply marking compound to

12 gear teeth of ring gear.

Rotate ring gear so that 12 gear

teeth are next to bevel pinion.

b.

Rotate ring gear (18) forward and

backward so that 12 marked teeth

go past bevel pinion six times to

get contact patterns . Repeat , if

necessary , to get a clearer

pattern.

c.

Inspect contact patterns on ring

gear (18) . Good hand rolled

pattern (H) will show contact

toward toe of gear tooth and in

the center between top and bottom

of tooth . A high pattern (I)

will show contact closer to top

of gear tooth . A low pattern (J)

will show contact toward bottom

of gear tooth . When in

operation , pattern will extend to

approximately full length of gear

tooth.

d.

If necessary , install thinner

shim pack (34) under pinion

bearing cage (30) to correct high

contact pattern.

e.

If necessary , install thicker

shim pack (34) under pinion

bearing cage (30) to correct low

contact pattern.

f.

If necessary , decrease backlash ,

STEP 3 , g . to move contact

patterns toward toe of ring gear

teeth.

g.

If necessary , increase backlash ,

STEP 3 , f . to move contact

patterns toward heel of ring gear

teeth.

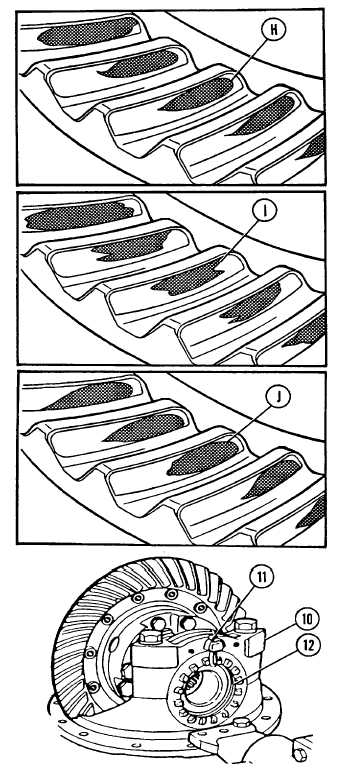

h.

Install two new cotter pins (11)

that hold two bearing adjusting

rings (12) in position . Install

cotter pins (11) through boss of

bearing cap (10) and between lugs

of adjusting ring (12).

9-29

|