| |

TM 10-3930-660-34

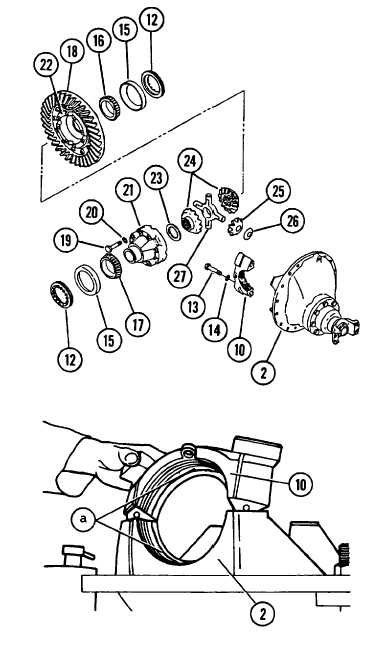

9-5 . REAR DIFFERENTIAL CARRIER ASSEMBLY - REPLACE/REPAIR/ADJUST (Cont’d)

d.

If torque value exceeds 50 lb.

ft. , disassemble differential.

Inspect case halves (21 and 22) ,

spider (27) , gears (24 and 25) ,

and washers (23 and 26) for

cause of high torque reading.

Replace parts as necessary.

8.

INSTALL DIFFERENTIAL AND RING GEAR

ASSEMBLY.

a.

Clean and dry bearing cups (15) ,

bores of differential carrier

(2) legs and bearing caps (10).

b.

Apply thin film of gear oil to

inner diameter of the bearing

cups (15) and on both bearing

cones (16 and 17).

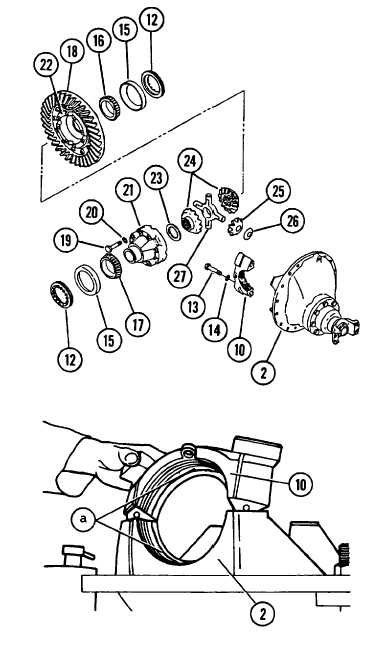

NOTE

When installing bearing cups (15) into

bearing bores of differential carrier

(2) apply Loctite #277 to bearing bores

(a) of differential carrier (2) and bearing

caps (10) . Do not allow Loctite #277 to

get into adjusting ring (12) threads.

c.

Apply thin bead of Loctite #277

to bearing bores of differential

carrier (2) legs and bearing

caps (10) . Do not apply Loctite

#277 to adjusting ring (12)

threads.

d.

Install two bearing cups (15)

over bearing cones (16 and 17) on

case halves (21 and 22).

9-24

|