| |

TM10-3930-660-34

8-5.

FRONT DIFFERENTIAL CARRIER ASSMEBLY - REPLACE/REPAIR/ADJUST (Cont’d)

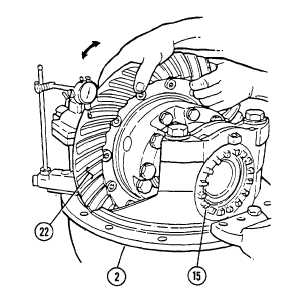

c. Rotate differential assembly and

ring gear (22) and read dial

indicator. If runout of ring

gear (22) exceeds 0.008 inches,

remove differential assembly and

ring gear (22), DISASSEMBLY

STEP 1, and inspect differential

assembly for problem. Replace

defective parts and reinstall

differential assembly and ring

gear (22) into differential

carrier (2), ASSEMBLY STEP 8.

Repeat preload adjustment of

differential bearings, STEP 1.

3.

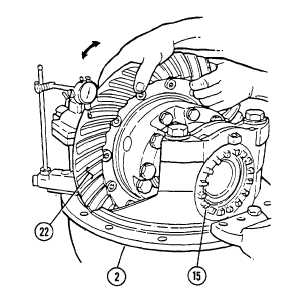

ADJUST BACKLASH OF RING GEAR (22).

a. Attach a dial indicator to the

mounting flange on differential

carrier (2).

b. Adjust dial indicator so that

plunger is against the tooth

surface on ring gear (22).

c. Adjust dial of indicator to zero.

d. Hold bevel pinion in position.

e. Read dial indicator while

rotating ring gear (22) a small

amount in both directions.

f.

Adjust backlash of old gear set

to setting measured before

carrier was disassembled (0.008

inch to 0.018 inch).

g. If new gear set is installed,

adjust backlash to 0.012 inch.

NOTE

When adjusting backlash, adjust only the

ring gear (22); do not adjust the bevel

pinion (12).

8-28

|