| |

TM10-3930-660-34

6-3. ALTERNATOR - REPAIR/TEST (Cont’d)

d. A high (infinite) resistance

reading in STEP c indicates an open

rotor winding and rotor (7) must

be replaced.

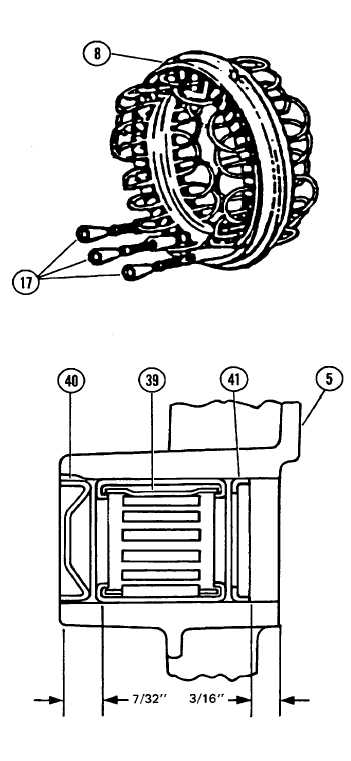

4. TEST STATOR (8) FOR OPEN OR GROUNDED

WINDINGS.

a. Using an ohmmeter set to low scale,

measure resistance through stator

windings. Connect ohmmeter to

terminal clips (17), from each

outside clip to center clip and

then between two outside clips.

b. Measure resistance from each

terminal clip (17) to stator frame

to check for grounded windings. A

low resistance reading between any

terminal clip (17) and stator frame

indicates a grounded winding, and

stator (8) must be replaced as a

unit.

ASSEMBLY

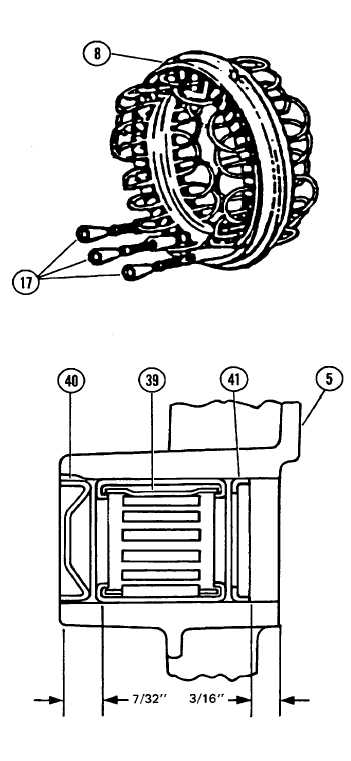

1. INSTALL ROLLER BEARING (39) TO SLIP

RING END FRAME (5).

a. Press new roller bearing (39) into

slip ring end frame (5) from

outside to inside, to a depth of

7/32 inch as shown.

b. Fill plug (40) with Delco-Remy

lubricant to a level sufficient to

fill grease reservoir

approximately one-half full.

c. Install plug (40), making sure that

some lubricant touches roller

bearing (39).

d. Press new seal (41) into slip ring

end frame (5) bore to a depth of

3/16 inch, as shown.

6-7

|