| |

TM10-3930-660-34

6-3. ALTERNATOR - REPAIR/TEST (Cont’d)

f. If necessary, remove nut (32),

connector (33), and battery

terminal assembly parts (34).

g. If necessary, remove relay terminal

cap (35), relay terminal assembly

parts (36), and connector (37).

h. If necessary, remove nut (38) and

wire lead (26) from regulator (28).

NOTE

If roller bearing (39) is not being

removed, apply pressure sensitive tape

over it for protection against dirt. Do

not use friction tape or other tape that

will leave a residue behind.

INSPECTION

i. If necessary for replacement,

1. INSPECT BEARINGS (14 AND 39) FOR ROUGH

push roller bearing (39) out of

ROTATION OR VISIBLE DAMAGE.

frame (5) and remove seal (41) and

plug (40). Discard seal (41).

2. INSPECT BRUSHES (20) FOR EXCESSIVE

WEAR.

j. If necessary, remove bushing

(42) and pin (43) from frame (5).

3. INSPECT BRUSH SPRINGS (31) FOR

DISTORTION OR DISCOLORATION

CLEANING

TESTING

1. CLEAN BRUSHES USING SOFT, DRY CLOTH.

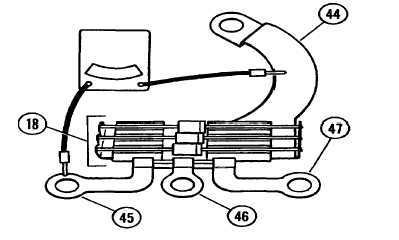

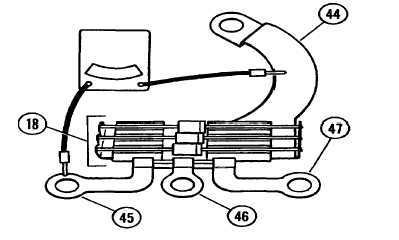

1. TEST DIODE TRIO (18).

2. CLEAN SLIP RINGS ON ROTOR (7).

a. Remove diode trio (18).

a. Place rotor (7) in a lathe, with

slip ring of shaft free.

b. Connect ohmmeter between diode trio

single connector (44) and each of

b. While rotor is spinning in lathe,

the other connectors (45, 46, and

hold No. 00 sandpaper or 400 grit

47) in turn. Observe resistance

silicon carbide paper against slip

reading on ohmmeter.

ring surface.

c. Reverse ohmmeter leads, or reverse

c. After polishing slip rings, clean

meter polarity, and repeat STEP b,

using low pressure (15 psi

above.

maximum) compressed air.

d. At one polarity, resistance reading

d. Clean ball bearing (14) in dry

should be low and at the other

cleaning solvent to remove

polarity, resistance reading should

lubricant.

be very high, if diodes are good.

6-5

|