| |

TM10-3930-660-34

4-3.

FUEL INJECTOR - TEST/REPLACE (Cont’d)

b. Operate pump lever at a rate that causes

nozzle to chatter softly while discharging

fuel in a broad and finely atomized pattern.

If conditions of prior note are not met,

replace nozzle.

INSTALLATION

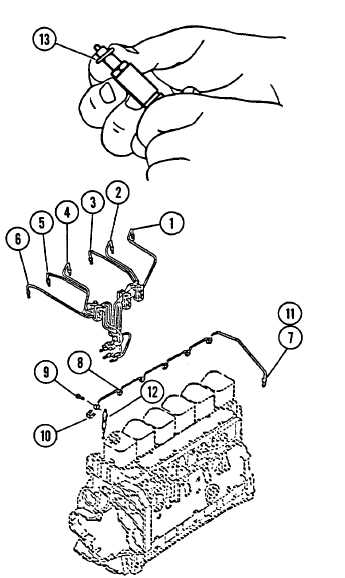

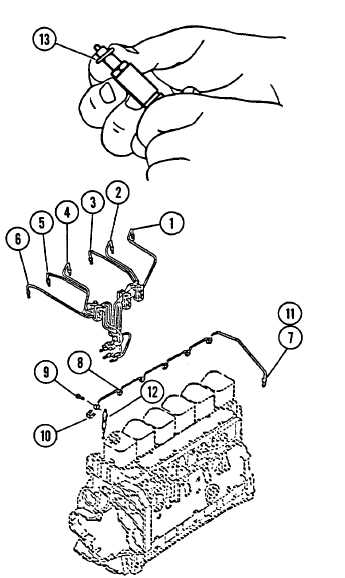

1. APPLY ANTI-SEIZE COMPOUND TO HOLD-

DOWN NUT THREADS.

2. INSTALL FUEL INJECTORS (12).

a. Install one new copper injector seal (13)

on each nozzle.

b. Install injector, (12) using care to align

button on injector nozzle holder with notch

in cylinder head bore.

c. Torque injector (12) nut to 44 lb. ft

d. Install new banjo connector seal (10) in

gap between nozzle holder and injector

nut.

e. Install fuel manifold (8) and new seals

(11), and secure to injectors with screws

(9). Tighten nuts (7) on manifold (8).

f. Loosely connect fuel high pressure tubes

(1-6) to fuel injectors. Leave connections

loose until bleeding procedure (STEP 3,

below) is completed.

3. CONNECT NEGATIVE BATTERY CABLE,

M10-3930-660-20.

4. BLEED FUEL SYSTEM.

WARNING

To bleed fuel system, engine must be

a. Briefly crank engine to allow air

placed in a run condition. Because

entrapped in high fuel pressure

engine may start during bleeding

lines to escape around fittings on

procedure, all necessary safety

fuel injectors.

precautions must be followed. See

TM10-3930-660-10 (unit operation manual).

b. Tighten fittings to 216 in. lb.

4-8

|