| |

TM10-3930-660-34

4-3.

FUEL INJECTOR - TEST/REPLACE (Cont’d)

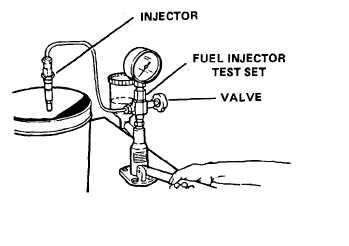

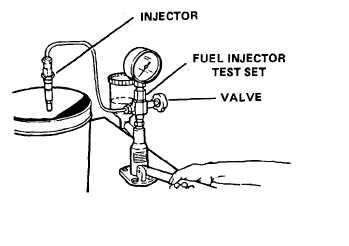

a. Connect injector to fuel injector test set.

b. Open valve and operate pump lever at a

rate of one stroke per second while

observing test pressure gauge.

c. Spray must begin at a pressure of

3553+73 psi.

d. If spray does not begin within pressure

range specified in STEP c, change

thickness of shims (20). Adding shims

will increase opening pressure. Remove

shims to decrease opening pressure.

e. Check for well atomized spray pattern.

2. LEAKAGE TEST.

a. Use same test setup as for opening

pressure test (STEP 1, above).

b. Open valve on test set.

c. Operate pump lever as necessary to

hold pressure at a level about 290 psi

below opening pressure noted in STEP

1c, above.

d. No drops must fall from nozzle tip for a

period of 10 seconds, while maintaining

pressure specified in STEP 2c, above.

If drops do appear within 10 seconds,

replace injector.

3. CHATTER TEST.

a. Use same test setup as for opening

pressure test (STEP 1, above).

NOTE

Do not evaluate used nozzles at lower

pumping rates. A used nozzle is serviceable if

it passes the leakage test, chatters audibly at

higher pumping rates and uniformly atomizes

fuel.

4-7

|