| |

TM 10-3930-660-34

3-18. CAMSHAFT, CAMSHAFT GEAR, AND CAMSHAFT BUSHING - REPLACE (Cont’d)

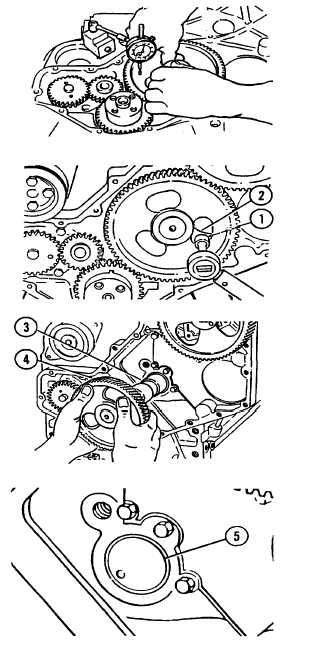

c. Measure camshaft end play using a dial indicator

positioned on a machined surface of the

camshaft gear. Record indicator reading for

reference

2.

TO PREVENT TAPPETS FROM DROPPING OUT

OF THE CYLINDER BLOCK WHEN CAMSHAFT

IS REMOVED, TURN ENGINE STAND SO THE

CRANKSHAFT IS FACING UP.

3.

REMOVE CAMSHAFT GEAR AND CAMSHAFT AS

AN ASSEMBLY.

a. Remove two capscrews (1) from thrust plate (2)

and remove thrust plate.

b. Slowly and carefully remove camshaft (3) and

gear (4), being careful not to damage the

camshaft lobes and bearing journals, and

camshaft bores in the cylinder block. It may be

necessary to slowly turn the camshaft, during

removal, to allow lobes to clear the tappets.

NOTE

If a new camshaft is to be installed, or if the

camshaft bushing is damaged or dimensions

exceed specified tolerance (see INSPECTION),

the camshaft bushing, and all service bushings

that may be installed in the other cam bores,

must be replaced.

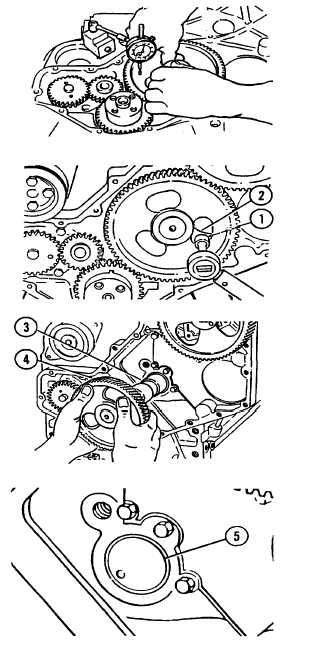

4.

IF NECESSARY, REMOVE CAMSHAFT BUSHING

(5) AND ALL CAM SERVICE BUSHINGS USING

THE UNIVERSAL BUSHING INSTALLATION

TOOL.

3-112

|