| |

TM 10-3930-660-34

3-15.

CONNECTING RODS AND BEARINGS - REPLACE (Cont’d)

INSPECTION

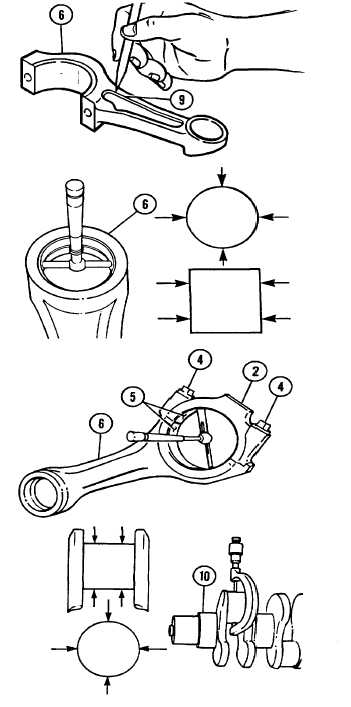

1.

VISUALLY INSPECT CONNECTING RODS (6) FOR

DAMAGE OR OBVIOUS WEAR.

2.

CHECK I-BEAM SECTION (9) OF CONNECTING

RODS (6) FOR DENTS OR OTHER DAMAGE. ANY

DAMAGE IN THIS AREA CAN CAUSE STRESS

WHICH WILL LEAD TO BREAKAGE.

3.

MEASURE I.D. OF PISTON PIN BORE IN

CONNECTING ROD (6), AT FOUR POINTS AS

SHOWN, TO CHECK FOR WEAR. TAKE AVERAGE

OF ALL READINGS. AVERAGE READING MUST

NOT EXCEED RANGE FROM 1.5769 TO 1.5784

INCH.

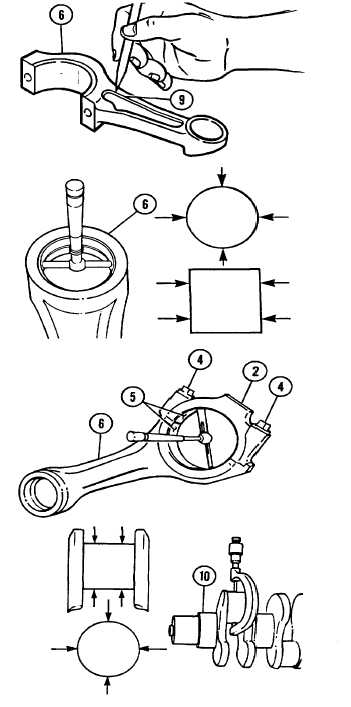

4.

CHECK ROD BEARING CLEARANCE.

a.

Assemble connecting rod (6), rod

bearings (5) and cap (2).

b.

Install capscrews (4) and tighten

to 73 lb. ft.

c.

Record smallest diameter measured at various

points around bore.

d.

Measure and record mean diameter of rod journal

on crankshaft (10). Take four readings on each

journal at points noted.

e.

Subtract rod journal mean diameter, STEP d,

from smallest rod bearing diameter, STEP c, to

determine rod bearing clearance.

NOTE

Maximum allowable rod bearing clearance is 0.0035 inch.

Select required undersized bearing set to compensate

for excessive rod bearing clearance.

3-101

|