| |

TM 10-3930-660-34

3-14.

PISTONS, PISTON PINS AND RINGS - REPLACE (Cont’d)

2.

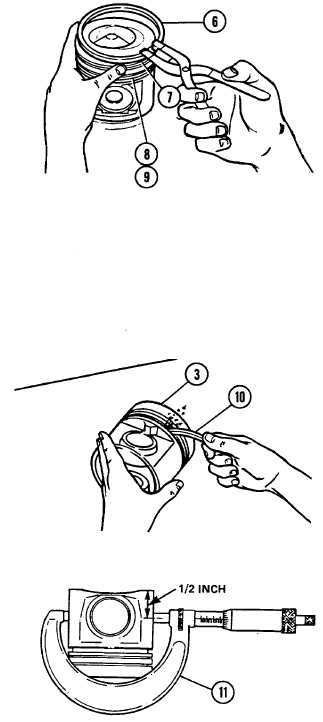

REMOVE AND DISCARD PISTON RINGS (6,

7 AND 8) AND OIL RING EXPANDER (9).

CLEANING

NOTE

Refer to Cleaning Instructions, para.

2-10, for general cleaning information

and for appropriate warnings regarding

use of solvents and compressed air.

CAUTION

Do not use bead blast to clean pistons.

Bead blasting may damage piston.

1.

SOAK PISTONS (3) IN DRY CLEANING

SOLVENT P-D-680 TO REMOVE CARBON

DEPOSITS.

2.

WASH PISTONS IN A STRONG SOLUTION OF

LAUNDRY DETERGENT AND HOT WATER, TO

REMOVE CARBON RESIDUE. USE A STIFF

BRISTLE BRUSH.

3.

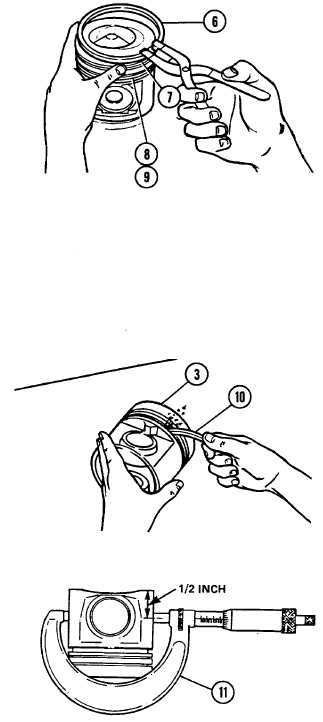

CLEAN RING GROOVES IN PISTON (3)

USING SQUARE END OF A BROKEN PISTON

RING (10). USE CARE TO AVOID

SCRATCHING RING SEALING SURFACES

IN PISTON GROOVES.

4.

CLEAN PISTONS AGAIN IN SOLUTION OF

LAUNDRY DETERGENT AND HOT WATER.

5.

RINSE PISTONS IN CLEAN, FRESH WATER

AND DRY USING COMPRESSED AIR.

INSPECTION

1.

VISUALLY INSPECT RING GROOVES,

PISTON TOP, PISTON SKIRT AND PISTON

PIN BORE FOR CRACKS OR OTHER DAMAGE

AND FOR EXCESSIVE WEAR.

2.

CHECK PISTON SKIRT DIAMETER USING AN

INSIDE MICROMETER (11) AS SHOWN, AT

A POINT APPROXIMATELY 1/2 INCH

ABOVE BOTTOM EDGE OF PISTON. MINIMUM

ALLOWABLE SKIRT DIAMETER IS 4.0088

INCH.

3-95

TM 10-3930-660-34

|