| |

TM 10-3930-660-34

3-9. CRANKSHAFT MAIN BEARINGS - REPLACE

This task covers:

a.

Removal

b.

Cleaning

c.

Inspection

d.

Installation

Initial Setup

Tools

Tool Kit, Automotive Mechanics

Shop Equipment, Automotive

Maintenance Common #2, Less Power

Fabricated Tool - Bearing Removal/

Installation Tool (App. C, Fig. C-7)

Shop Equipment, Automotive Maintenance

and Repair; Field Maintenance, Basic,

Less Power

Equipment Condition

Vehicle parked on level ground.

Oil pan removed, para. 3-20.

Oil suction tube removed,

para. 3-21.

Materials/Parts

Dry Cleaning Solvent P-D-680 (App. B,

Item 48)

Lint-Free Rags (App. B, Item 38)

Lubricating Oil (App. B, Item 26)

Lubriplate 105 (App. B, Item 16)

REMOVAL

1.

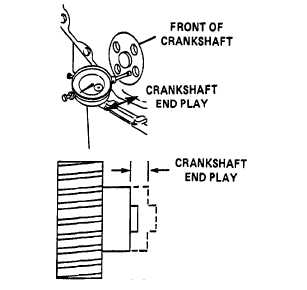

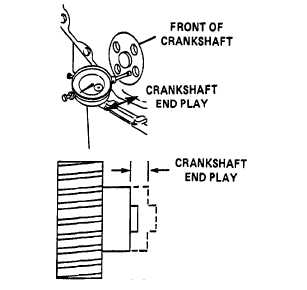

CHECK CRAKSHAFT END PLAY.

a.

End play is controlled by the dimensions of

the thrust bearing and crankshaft journal at

the number 6 main bearing position.

b.

Measure crankshaft end play using a dial

indicator as shown in this illustration.

c.

Push crankshaft forward, then toward rear

of engine. Record end play measurement.

This data will be needed later during thrust

bearing installation.

2.

REMOVE MAIN BEARINGS (3 AND 4) FROM

MAIN BEARING LOCATIONS 2 THROUGH 6.

Bearing removal instructions for main bearings 1 and 7

will be covered in the INSTALLATION paragraph.

3-67

|