| |

TM 10-3930-660-34

3-8.

CRANKSHAFT - REPLACE/REPAIR

(Cont’d)

2. APPLY LUBRICATING OIL TO ALL CRANKSHAFT

BEARING JOURNALS IF CRANKSHAFT IS NOT

GOING TO BE INSTALLED WITHIN ONE HOUR

AFTER CLEANING.

INSPECTION

1. SEE INSPECTION INSTRUCTIONS, PARA. 2-11.

2. VISUALLY INSPECT CRANKSHAFT.

a.

Inspect for large, deep cracks or broken material

throughout the crankshaft, especially in the

fillet and journal areas.

b.

Inspect for a high concentration of depressions or

pitting.

c.

Inspect for burning or scoring in the journal areas.

d.

If any of the conditions mentioned in STEPS a

through c exist, replace the crankshaft.

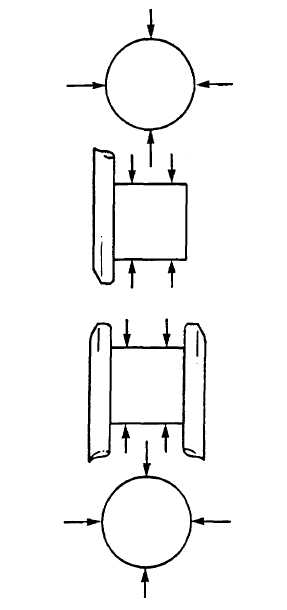

3. MEASURE CRANKSHAFT BEARING JOURNALS.

a.

Measure crankshaft main bearing journals. If any

main bearing journal measures less than

3.2662 inches, replace the crankshaft or use

oversize bearings. If any main bearing journal

is out of round by more than 0.0020 inch,

replace crankshaft or machine crankshaft and

use oversize bearings.

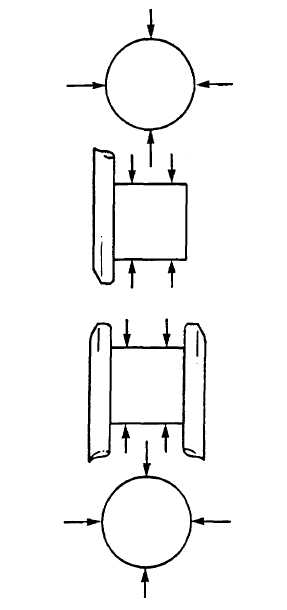

b.

Measure crankshaft connecting rod journals. If any

connecting rod journal measures less than

2.7150 inches, replace the crankshaft or use

oversize bearing. If any connecting rod

journal is out of round by more than 0.0020

inch, replace crankshaft or machine

crankshaft and use oversize bearings.

3-56

|