|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

MLRS ATTACHMENT CONTROL VALVE MAINTENANCE - CONTINUED

0304 00

DISASSEMBLY - CONTINUED

15.

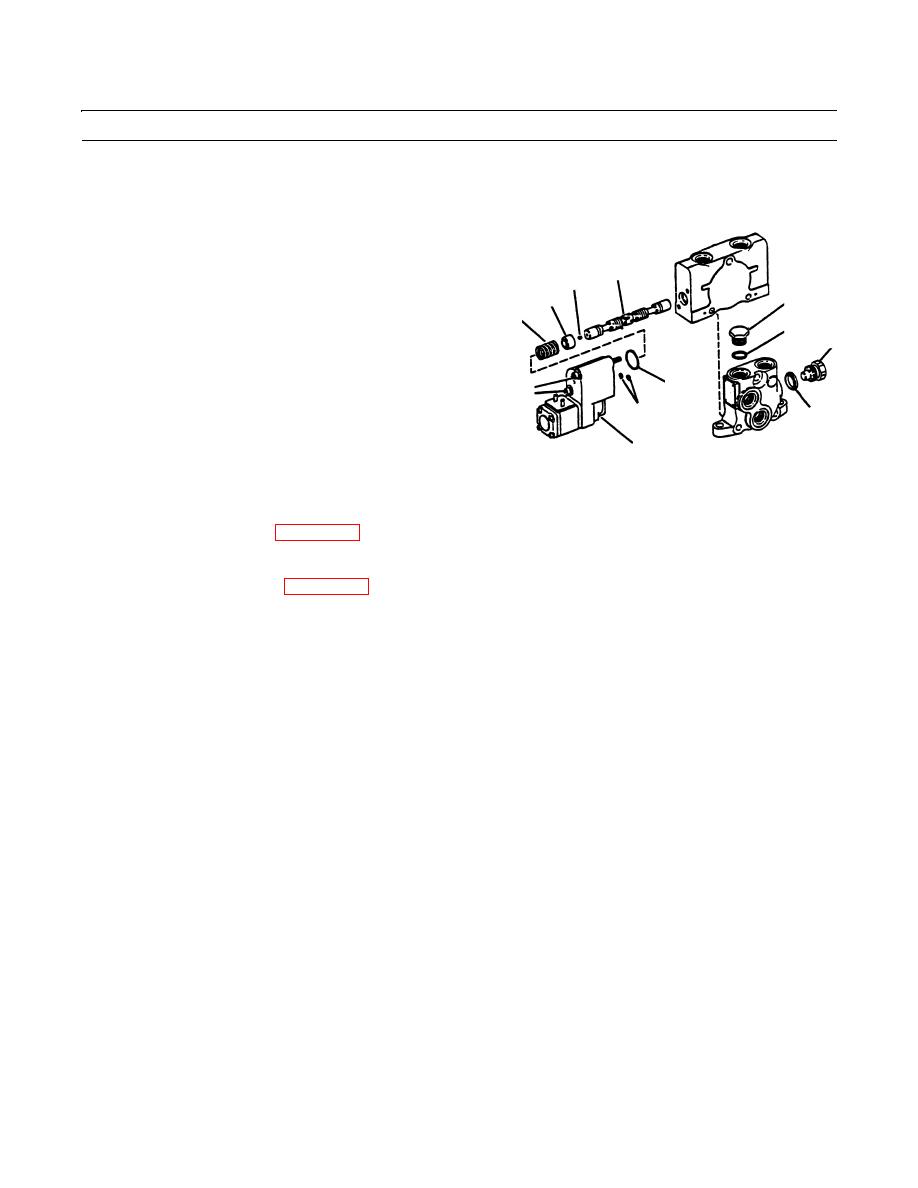

Remove two bolts (47), flatwashers (48) and lockwashers (49) from each electric hydraulic proportioning (EHP) assem-

bly (50). Remove eight EHP assemblies. Discard lockwashers.

16.

Remove and discard two small O-rings (51) and one

large O-ring (52) from each EHP assembly (50).

58 55,56,57

17.

Remove spring (53) and spring seat (54) from each

54

59

housing section.

53

60

18.

Remove spools (55 and 56) and two spools (57) from

61

housing sections.

19.

Remove plug (58) from each spool.

52

47,48,49

51

20.

Remove plug (59) and O-ring (60), if necessary. Dis-

62

card O-ring.

50

409-1382

21.

Remove plug (61) and O-ring (62), if necessary. Dis-

card O-ring.

CLEANING

See Cleaning instructions (WP 0316 00).

INSPECTION

See Inspection instructions (WP 0317 00).

ASSEMBLY

NOTE

Wipe all sealing surfaces on valve clean and dry. Apply film of clean hydraulic oil to all seals as they are

installed.

1.

If removal of O-ring (62) and plug (61) was necessary, install plug (61) with new O-ring (62).

2.

If removal of O-ring (60) and plug (59) was necessary, install plug (59) with new O-ring (60).

3.

Install plug (58) into each spool (55 thru 57).

4.

Install spools (55 and 56) and two spools (57).

5.

Install spring seat (54) and spring (53) in each housing section.

6.

Install two new small O-rings (51) and one new large O-ring (52) to each EHP assembly (50).

7.

Install eight electric hydraulic proportioning (EHP) assemblies (50) with new lockwashers (49), flatwashers (48) and

two bolts (47).

0304 00-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |