|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

FRONT DIFFERENTIAL CARRIER ASSEMBLY MAINTENANCE - CONTINUED

0296 00

ASSEMBLY - CONTINUED

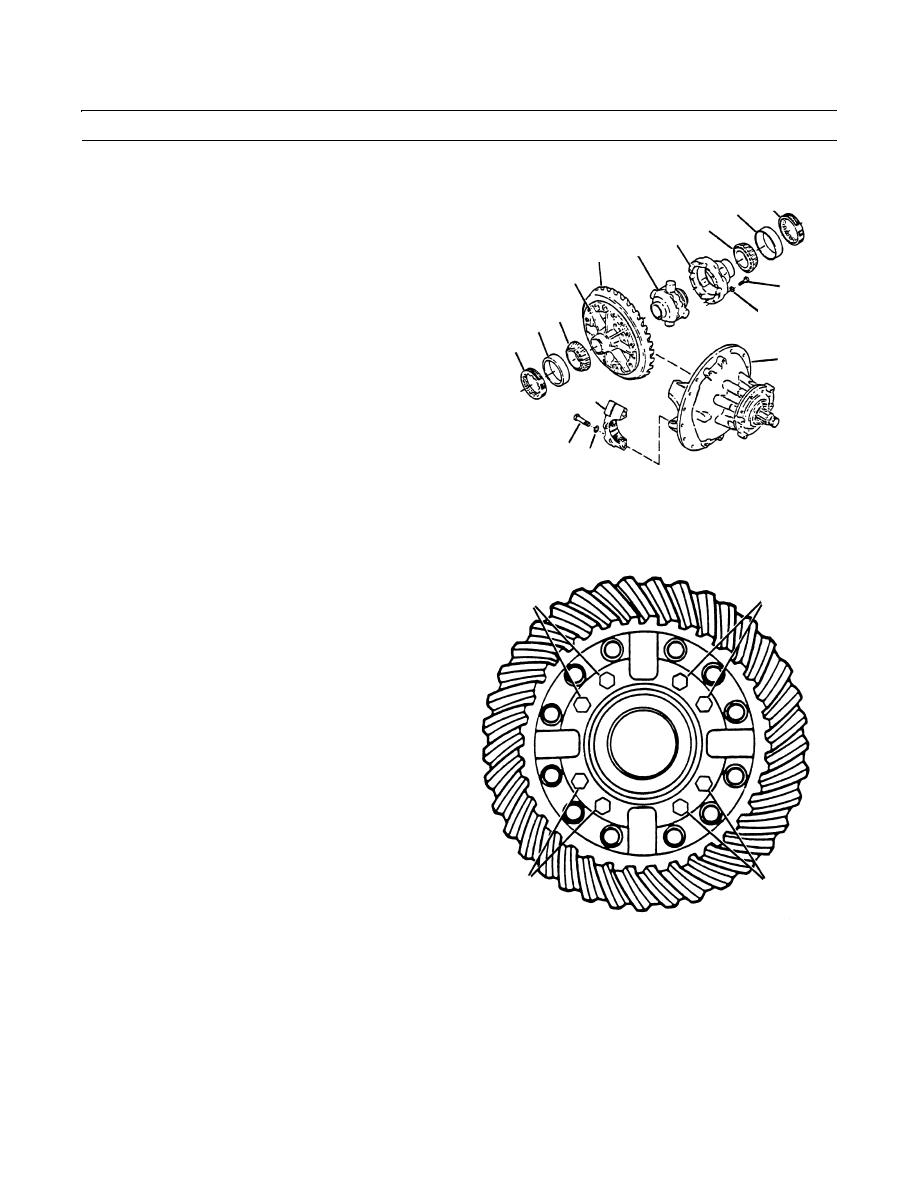

41.

Use a press and sleeve to install bearing cone (10) on

4

9

flange case half (17).

11

16

12

42.

Use a press and sleeve to install bearing cone (11) on

13

plain case half (16).

17

14

43.

Apply clean lubricant to inside surfaces of both case

10

halves (16 and 17) and no-spin differential (12).

15

9

4

44.

Place flange case half (17) on bench, ring gear (13)

8

teeth up.

2

45.

Install no-spin differential (12) into flange case half

(17).

46.

Place plain case half (26) over flange case half (17)

67

and no-spin differential (12). Rotate plain case half

409-1249

(16) as needed to align match marks.

47.

Apply loctite to eight capscrews (14). Install four of the eight capscrews (14) and four flatwashers (15) at opposing pairs

(X and Y) into case halves (16 and 17).

CAUTION

Y

X

14,15

14,15

Spacing between four initially installed

capscrews must be even to prevent uneven

pressure on case halves when torquing.

Failure to do so could cause component

failure.

48.

Torque four capscrews (14) to 60-75 lb-ft (81-102

Nm).

NOTE

Torque capscrews in pairs on opposing

sides of ring gear.

49.

Install remaining four capscrews (14) and four flat-

washers (15). Torque capscrews to 60-75 lb-ft (81-102

14,15

14,15

Nm).

Y

X 409-1250

50.

Remove no spin retaining bolt, flatwashers and wing

nut.

NOTE

When installing bearing cups, apply loctite to bearing bores of differential carrier legs and bearing caps. Do

not apply loctite to adjusting ring threads.

Clean and dry bearing cups, bores of differential carrier, legs and bearing caps.

51.

Apply thin film of gear oil to inner diameter of the bearing cups (9) and on both bearing cones (10 and 11).

0296 00-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |