|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

FRONT DIFFERENTIAL CARRIER ASSEMBLY MAINTENANCE - CONTINUED

0296 00

ASSEMBLY - CONTINUED

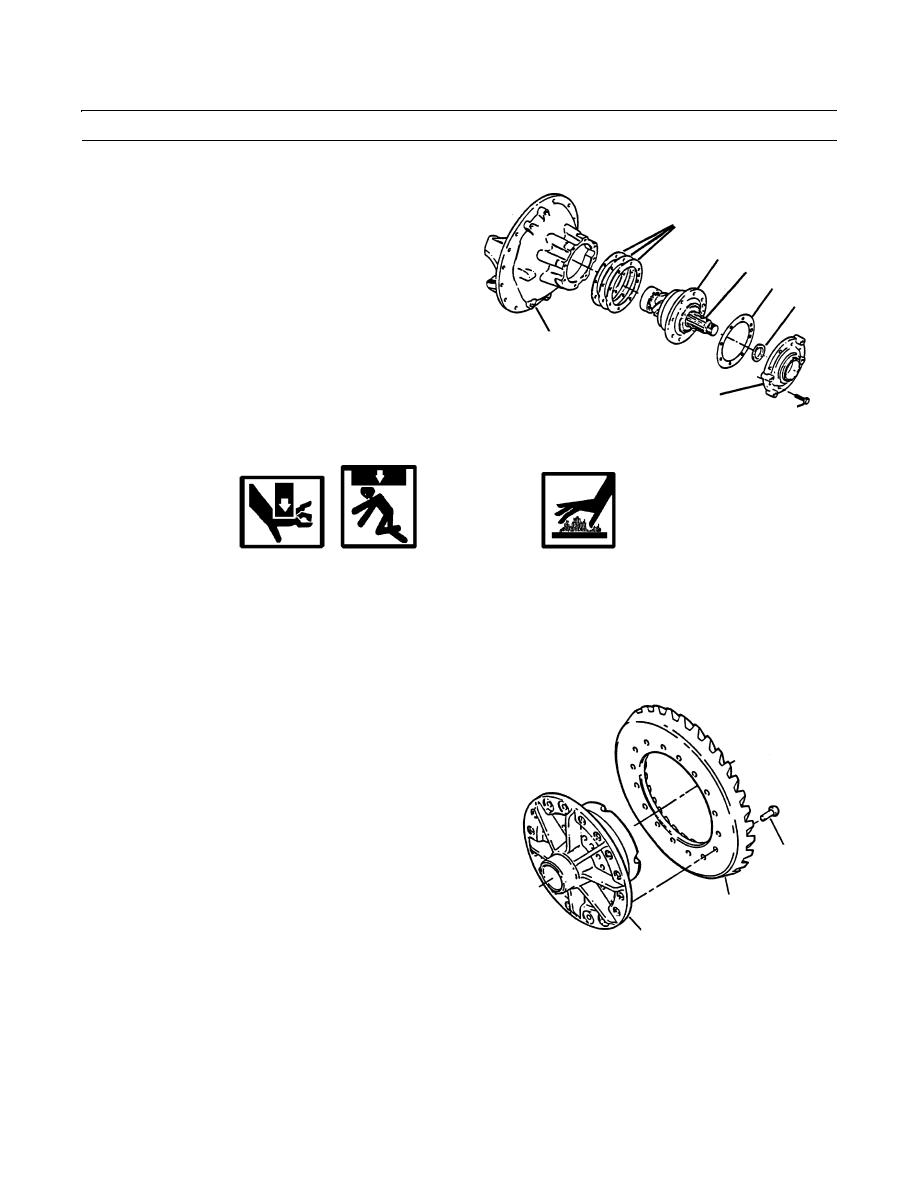

32.

Install pinion bearing cage thrust washer (24) on bevel

pinion (19).

26

33.

Place bearing cage cover (22) onto bearing cage (20)

20

and secure with eight capscrews (21).

19

34.

Torque capscrews (21) to 50-75 lb-ft (68-102 Nm).

25

24

8

22

21

409-1246

WARNING

Wear gloves and proper clothing while handling hot ring gear. Failure to follow this precaution could result

in serious personal injury.

Ring gear must be heated before installation. Failure to heat ring gear before installation could cause damage

to differential case half because of tight fit.

Use caution when handling heavy parts. Provide adequate support and use assistance during procedure. Ensure

that any lifting device used is in good condition and of suitable load capacity. Keep clear of heavy parts sup-

ported only by lifting device. Failure to follow this warning may cause injury or death.

35.

Expand ring gear (13) by heating in a tank of water to

a temperature of 160 to 180F (71 to 82C) for 10 to

15 minutes.

36.

Use a sling and hoist to lift the ring gear (13) from

tank of water.

37.

Install ring gear (13) on flange case half (17) immedi-

ately after heating. If ring gear (13) does not fit easily

on flange case half (17), repeat step 41.

18

38.

Align fastener holes of ring gear (13) and flange case

half (17) by rotating ring gear (13) as needed.

13

17

409-1240

0296 00-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |