|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

ALTERNATOR ASSEMBLY MAINTENANCE (152 HP) - CONTINUED

0284 00

TESTING

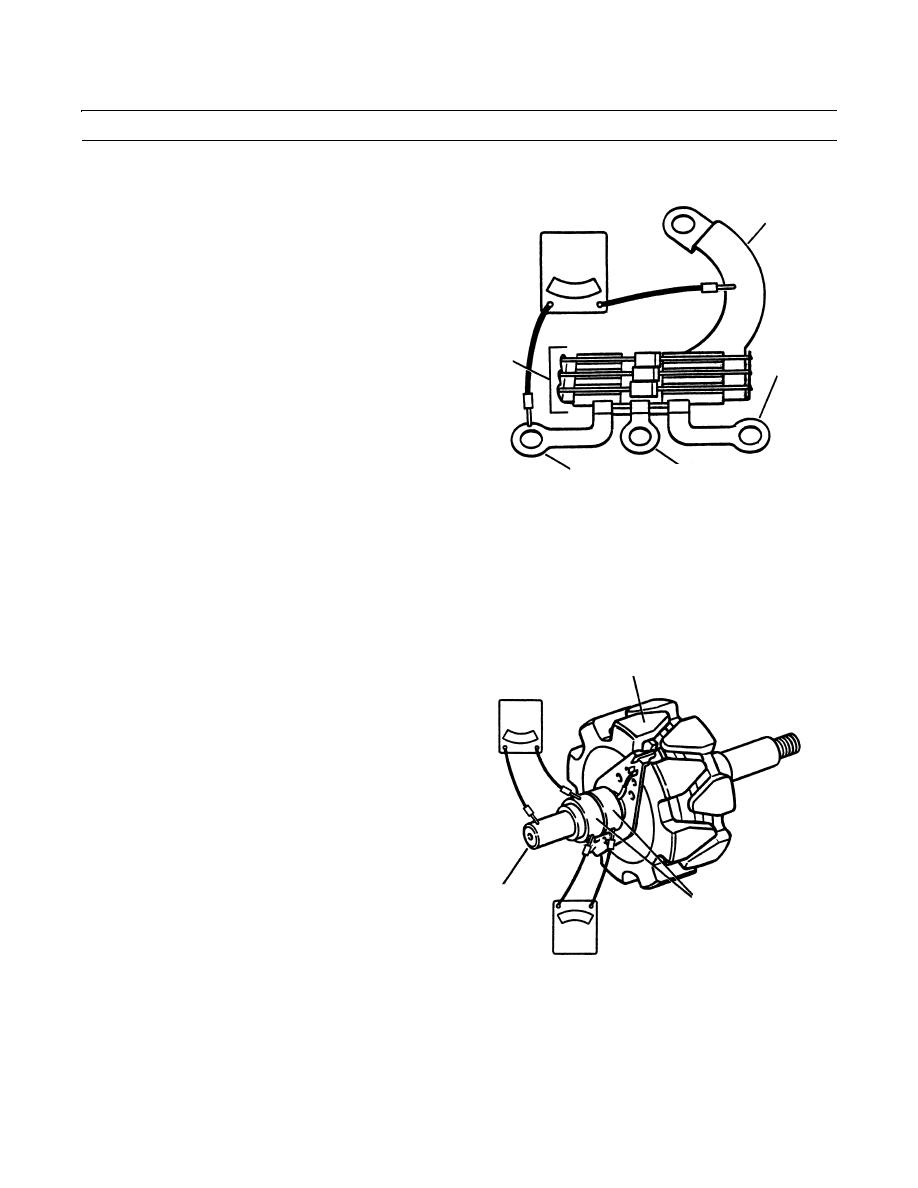

1.

To test diode trio (18), connect ohmmeter between

44

diode trio single connector (44) and each of the other

connectors (45 thru 47) in turn. Observe resistance

reading on ohmmeter.

2.

Reverse ohmmeter leads, or reverse meter polarity and

repeat step 3 above.

3.

At one polarity, resistance reading should be low and

at the other polarity, resistance reading should be very

18

high, if diodes are good.

47

4.

If both readings on same set of connectors are either

high or low, the associated diode is faulty and entire

diode trio must be replaced.

46

409-1099

45

5.

To test rectifier bridge (23), connect ohmmeter from grounded heat sink (48) to diode terminal (49) and note resistance

reading.

6.

Reverse ohmmeter leads or reverse meter polarity and again note resistance reading.

7.

At one polarity, resistance reading should be low and at the other polarity, resistance reading should be very high, if

diode is good. If diode if faulty, both readings will be either low or high.

8.

Repeat above sequence between grounded heat sink

7

(48) and diode terminals (50 and 51), and then

between insulated heat sink (52) and each diode termi-

A

nal (49 thru 51).

9.

If any set of readings indicates a faulty diode, replace

complete rectifier bridge (23).

10.

To test rotor (7) for short or open circuits, connect

ohmmeter between slip rings (53), in turn, and rotor

shaft (54) (connection A). Observe resistance reading

on ohmmeter.

54

53

B

409-1101

11.

Resistance reading should be high (infinite). If not, rotor (7) is defective and must be replaced.

12.

Connect ohmmeter leads across slip rings (53) (connection B). Observe resistance reading on ohmmeter.

13.

A high (infinite) resistance reading indicates an open rotor winding and rotor (7) must be replaced.

0284 00-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |