|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

CRANKSHAFT MAIN BEARINGS MAINTENANCE - CONTINUED

0272 00

INSTALLATION - CONTINUED

NOTE

When bearings are reused, each bearing must be installed in its original location because the bearing sur-

faces have worn to the crankshaft journals.

43.

Check no. 1 main bearing clearance by using installation steps 15 thru 20.

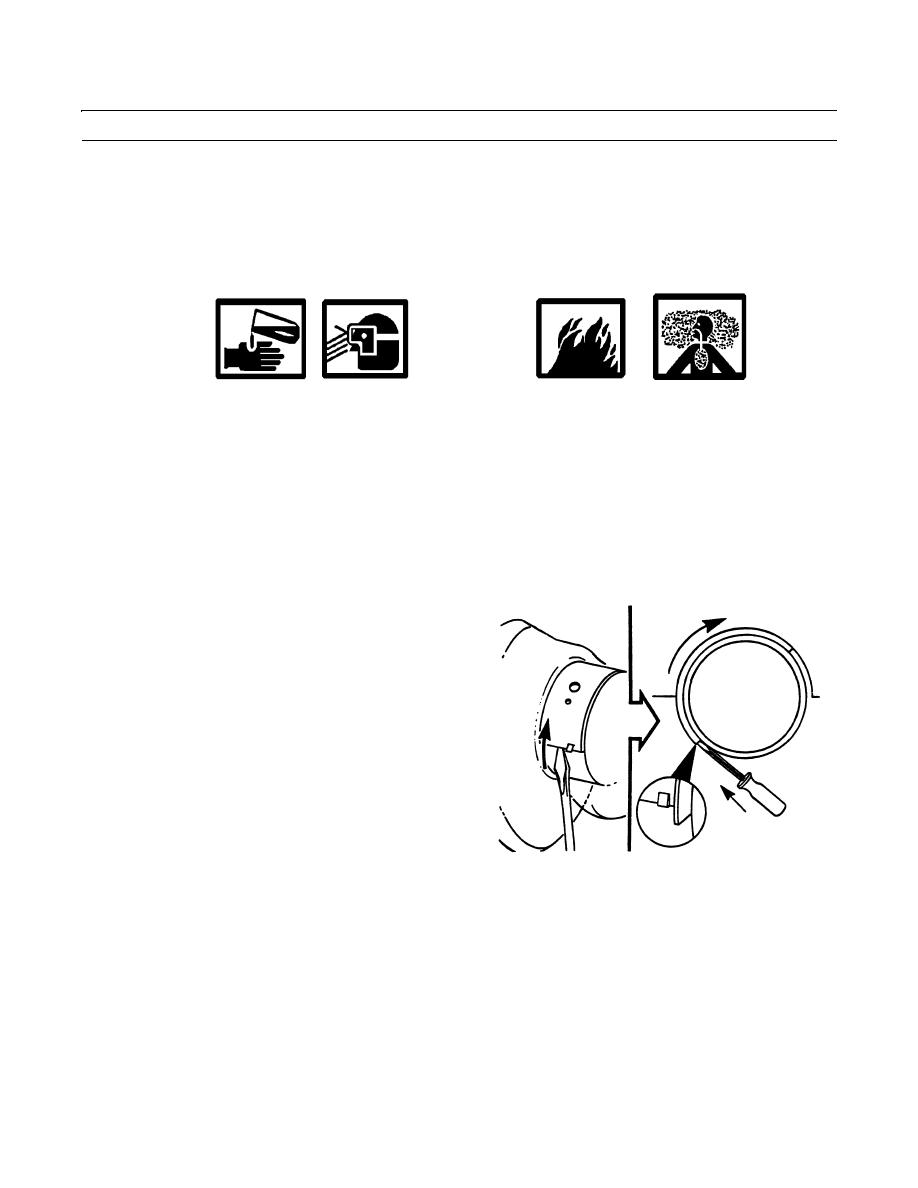

WARNING

Particles blown by compressed air are hazardous. DO NOT exceed 15 psi (103 kPa) nozzle pressure when

drying parts with compressed air. Use a maximum of 30 psi (207 kPa) when cleaning components. DO

NOT direct compressed air against human skin. Failure to follow this warning may cause injury or death.

Make sure air stream is directed away from user and other personnel in the area. To prevent injury, user

must wear protective goggles or face shield.

To help prevent damage to the cylinder block during main bearing bore cleaning, compressed air shall not

exceed 15 psi (103 kPa).

Cleaning compound, solvent MIL-PRF-680 Type III is an environmentally compliant and low toxic material.

However, it may be irritating to the eyes and skin. Use protective gloves and goggles. Use in well-ventilated

areas. Keep away from open flames and other sources of ignition.

CAUTION

To help prevent damage to the cylinder

block during main bearing bore cleaning,

compressed air shall not exceed 15 psi.

Use compressed air only with effective

chip guarding and personal protective

equipment.

NOTE

If main bearings are coated with oil,

remove oil with a clean wiping rag.

44.

Clean main bearing surfaces in the cylinder block and

409-4112

bearing caps with solvent cleaning compound. Dry

surfaces thoroughly with low pressure compressed air

15 psi (103 kPa) maximum.

0272 00-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |