|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

CRANKSHAFT MAIN BEARINGS MAINTENANCE - CONTINUED

0272 00

INSTALLATION - CONTINUED

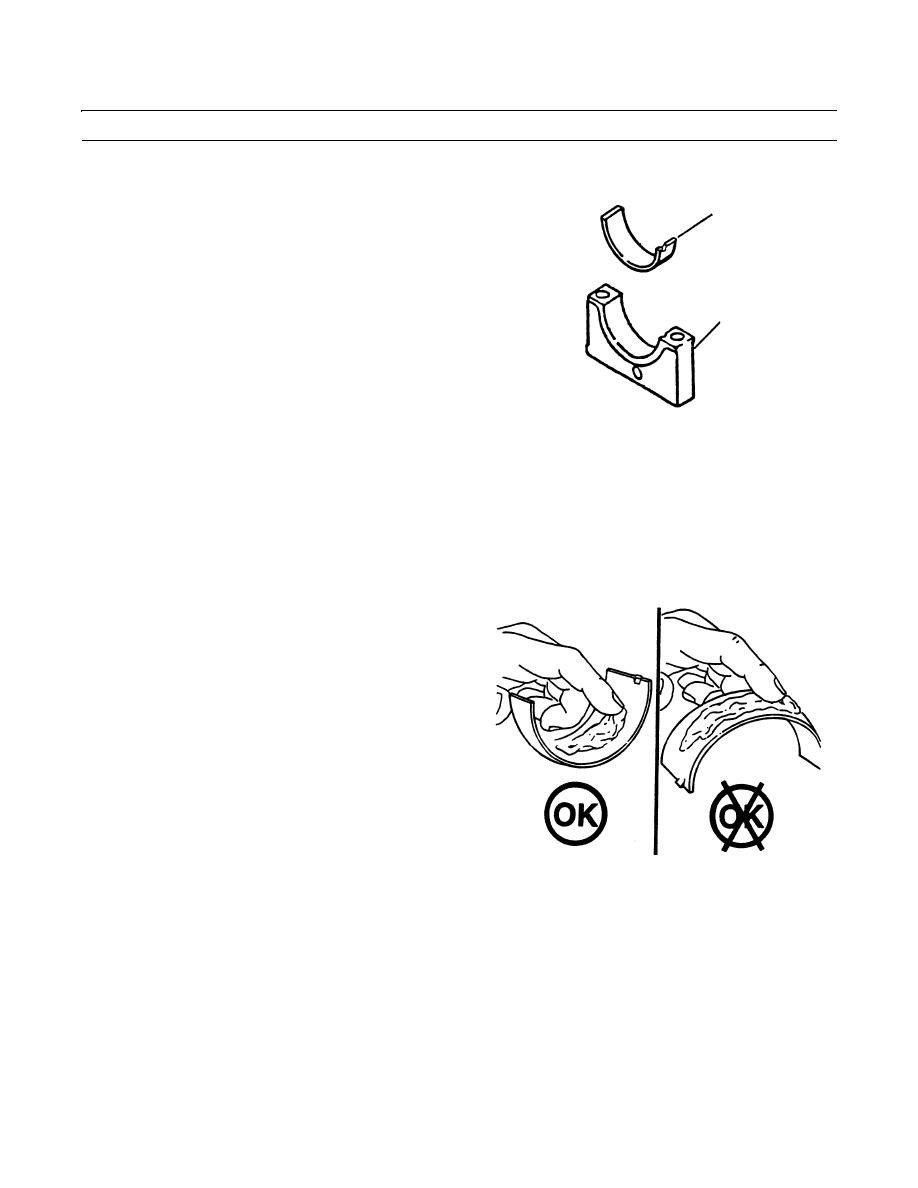

19.

Remove bearing removal/installation tool from crank-

4

shaft oil hole.

20.

Remove lower bearing half (4) from bearing cap (2).

Keep main bearings and bearing caps together as a set.

2

409-937

NOTE

When bearings are reused, each bearing set must be installed in its original location because the bearing sur-

faces have worn to the crankshaft journals.

21.

Repeat steps 15 thru 20 for remaining main bearings and thrust bearing (5) at main bearing position no. 6.

22.

To install bearings, be sure bearing bore surfaces in the cylinder block are clean and dry.

23.

Check that the backsides of main bearings are clean and dry.

24.

Check that inside surfaces of bearing caps are clean

and dry.

25.

Apply lubriplate to the inside surface of upper bearing

half (3). Do not lubricate the side that is against the

cylinder block bearing bore.

26.

Install one bearing set at a time. Install upper main

bearing half (3) over the crankshaft journal such that

the bearing tab will fit into the notch in cylinder block.

If used main bearing is being installed, install main

bearing half in the same position it was removed from.

If a new bearing is being installed, use the correct size

bearing as determined in steps 17 thru 19 above.

409-4110

0272 00-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |