|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

CYLINDER HEAD ASSEMBLY REPAIR - CONTINUED

0270 00

REPAIR - CONTINUED

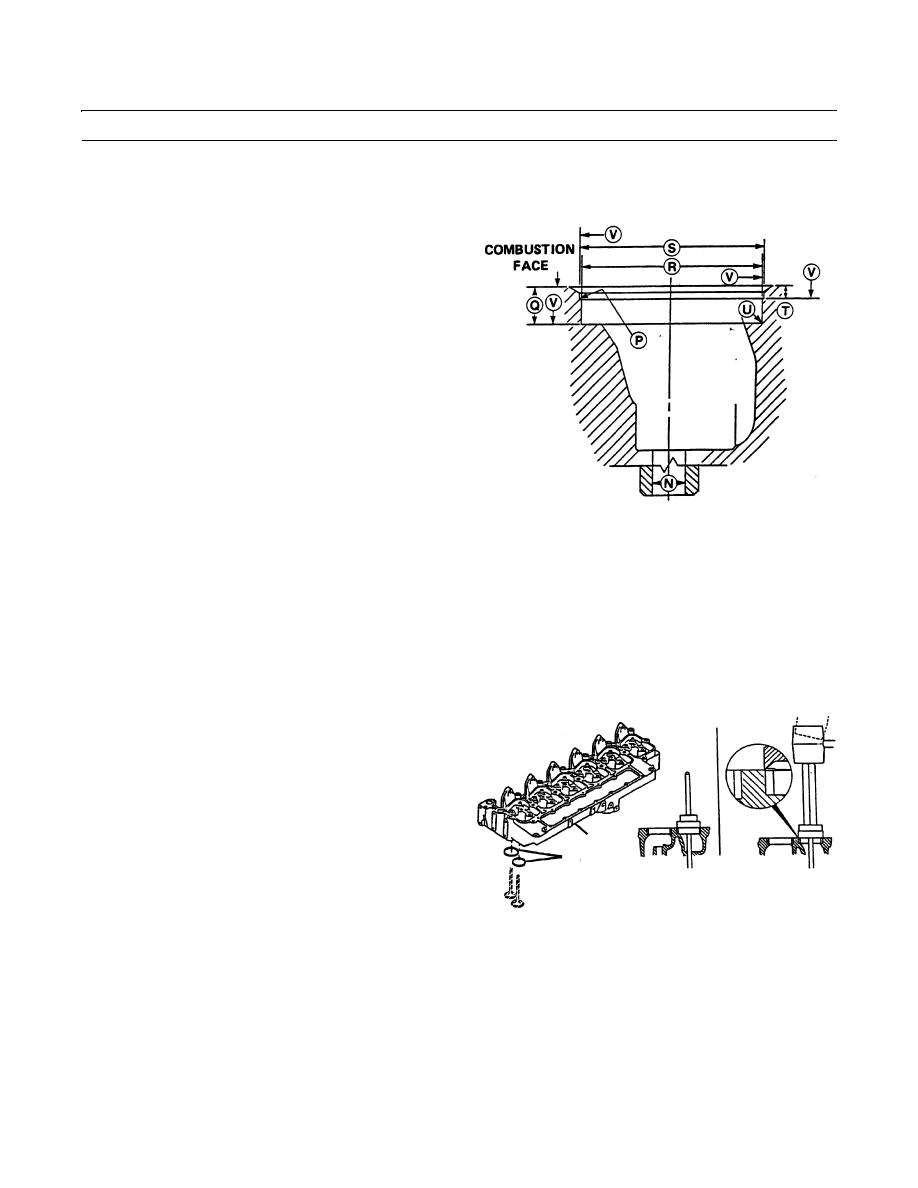

35.

Machine parent metal intake valve seat pocket to the dimensions shown.

N

0.3157 to 0.3165 in. (8.0187 to 8.0391 mm)

P

0.015 in. (0.381 mm) radius max.

Q

0.3795 to 0.4055 in. (9.6393 to 10.2997 mm)

R

1.7180 to 1.7190 in. (43.6372 to 43.6626 mm) dia

S

1.7489 to 1.7589 in. (44.422 to 44.676 mm) dia.

T

0.1379 to 0.1479 in. (3.5026 to 3.7566 mm)

U

0.0157 in. (0.3987 mm) radius max.

V

128 microinch surface finish

409-910

36.

Install exhaust valve service seats (9) in cylinder head (10) in the same manner described for the intake service seats.

See steps 27-35 above.

NOTE

If it cannot be accurately determined that service valve seats have been ground only once after initial instal-

lation, replace the seat.

Valve seats marked with two X's on the cylinder head have service seats installed. Service seats, like the par-

ent metal seats, can only be ground once after initial installation.

37.

Grind valve service seat(s). Grind service seats (15)

for a few seconds only, to avoid making them too

wide.

38.

Grind service seats in the same manner, and to the

same tolerances, as used for grinding the integral seat

in steps 16 thru 31 above.

10

9

409-880

0270 00-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |