|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

CYLINDER HEAD ASSEMBLY REPAIR - CONTINUED

0270 00

CLEANING - CONTINUED

7.

Remove valves according to their location in the cylinder head.

8.

Clean valve springs with dry cleaning solvent and dry thoroughly with compressed air.

INSPECTION

1.

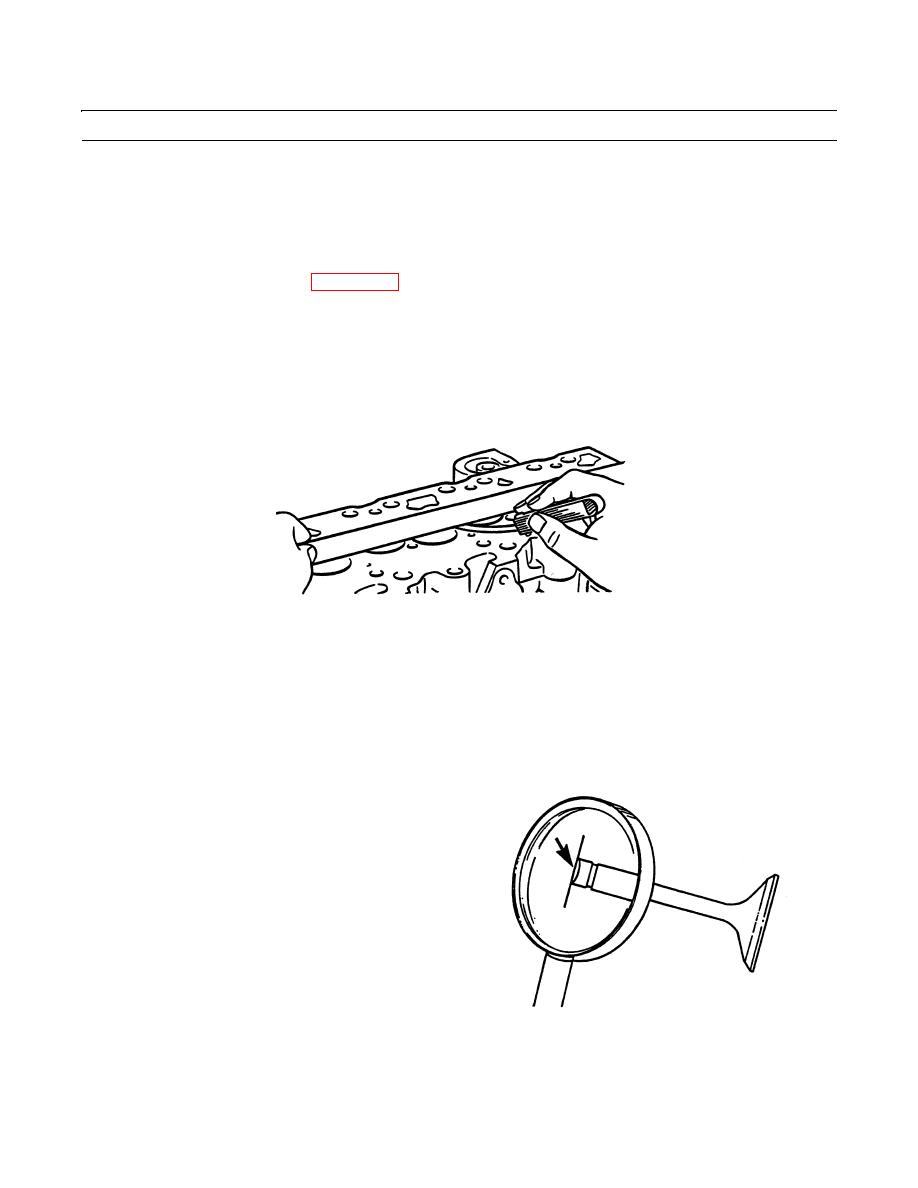

To inspect cylinder head assembly (WP 0317 00), check for uneven surfaces and warpage of cylinder head.

2.

Place a straightedge along length of cylinder head mating surface and check for distortion.

3.

Measure gap under straightedge in areas indicated in chart.

NOTE

If warpage, uneven surfaces, or distortion are found, cylinder head assembly must be replaced.

409-858

Measured Area

Variation Limit

Any 2 in. (5 cm) dia. area

0.004 in. (0.1016 mm)

Overall end-to-end

0.003 in. (0.0762 mm)

Overall side-to-side

0.003 in. (0.0762 mm)

4.

Inspect valves. Grind all reused valves. Mark new

valves respective to their location in the cylinder head.

5.

Inspect valve stems for scratches or scuff marks.

Replace valve if scratches or scuffing is found.

6.

Inspect valve faces for ridges, cracks, or pitting.

Replace valve is ridges, cracks or pitting is found.

7.

Check valve stem tip for flatness and replace valve if

necessary.

409-859

0270 00-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |