|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

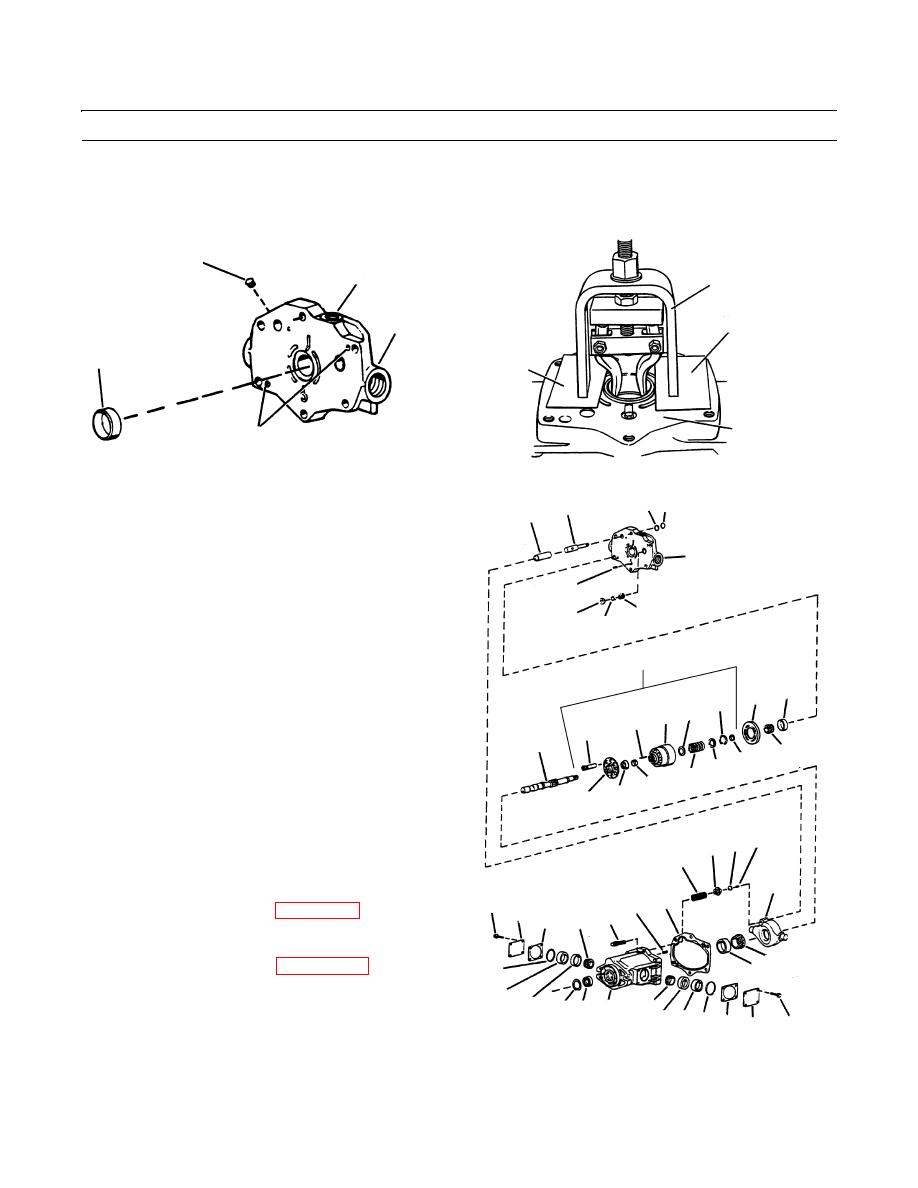

PISTON PUMP MAINTENANCE - CONTINUED

0256 00

DISASSEMBLY - CONTINUED

29.

Disassemble valve block (3), if necessary.

45

A

PULLER

TOOL

3

SHIM

STOCK

48

SHIM

STOCK

3

B

409-1485

409-1478

NOTE

47 46

8

7

Do not disassemble check valve parts

unless there is a problem with valve opera-

3

tion. See Inspection steps 3 and 8.

12

30.

If necessary, remove seat (42), valve (43) and spring

(44) from valve block (3).

44

42

43

31.

Remove plug (45), O-ring (46), retaining ring (47) and

piston rod (8) from valve block (3).

18

NOTE

48

11

21

Be careful not to scratch the face of the

17 23

16

valve block during bearing race removal.

23

15

32.

Use fabricated tool and shim stock to remove bearing

13

22 14

race (48) from valve block (3).

20

25

33.

If necessary, remove two alignment pins (49) from

24

19

housing (6).

34.

If necessary, remove two plugs (50) from compensator

34 36 37

(1).

35

26

CLEANING

49 10

28 29

9

See Cleaning instructions (WP 0316 00).

27

31

INSPECTION

38

See Inspection instructions (WP 0317 00).

1.

39

32

2.

Turn piston (7) on rod (8) 360 degrees. If binding

33

30

31

40 41 6

occurs, replace piston and rod.

30 33 32 27 29

28

3.

Check that check valve seat (42) is tight within valve

409-1473

block (3) and that it does not protrude above the valve

block face.

0256 00-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |