|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

FRONT PLANETARY WHEEL ENDS REPLACEMENT - CONTINUED

0244 00

REMOVAL - CONTINUED

20.

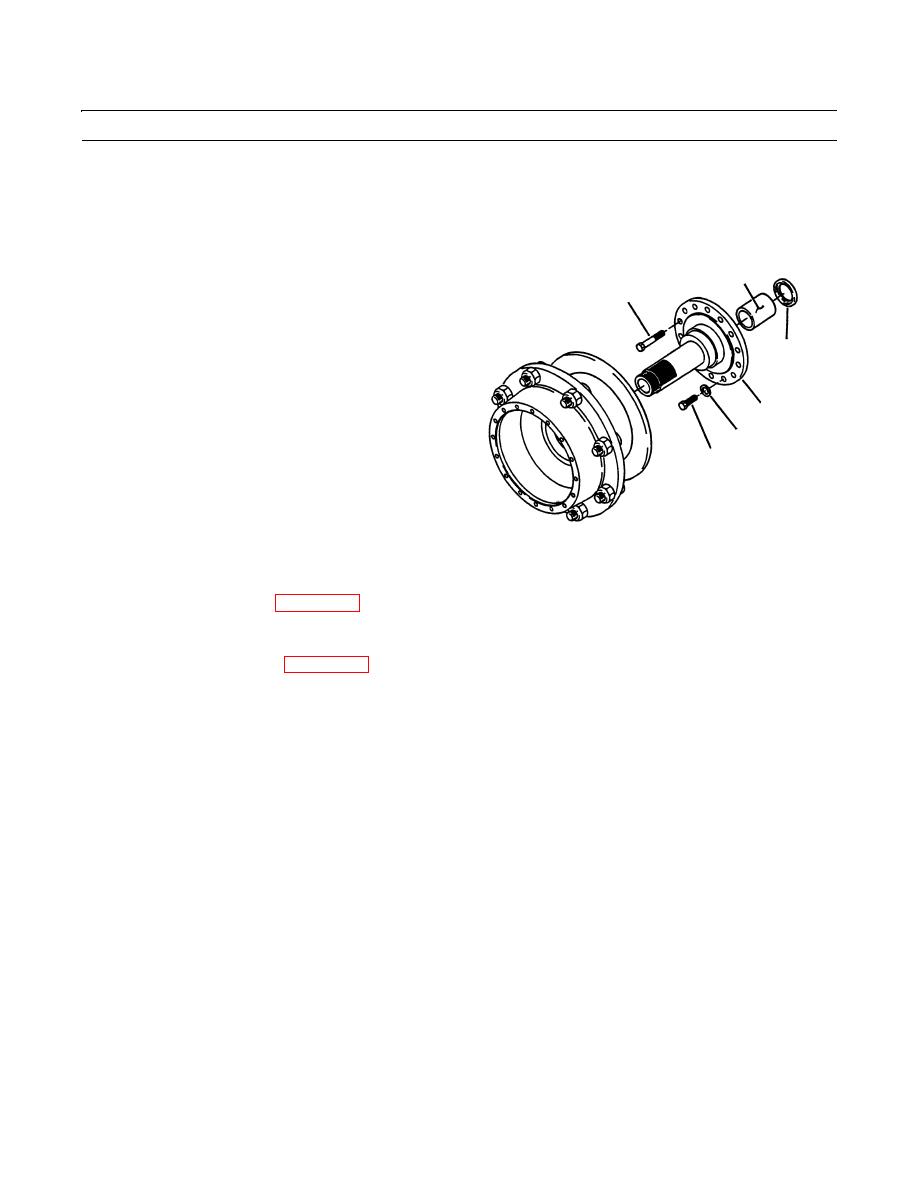

To remove spindle assembly, remove ten spindle capscrews (21), four shorter capscrews (22), and fourteen flatwashers

(23).

CAUTION

24

Inner oil seal and bushing in bore of spin-

21

dle can be damaged when sliding spindle

past axle splines. Remove spindle care-

fully to avoid damaging bushing and inner

25

oil seal. Failure to do so could cause pre-

mature component failure.

21.

Remove wheel bearing spindle (10).

10

22.

Remove and discard oil seal (25).

23

23.

If necessary, remove bushing (24).

22

409-1265

CLEANING

See Cleaning instructions (WP 0316 00).

INSPECTION

See Inspection instructions (WP 0317 00).

INSTALLATION

1.

If removed, push bushing (24) into spindle (10) until top of bushing is flush or just below bottom of bore for new oil seal

(25).

2.

Push new oil seal (25) to bottom of bore.

3.

Apply a thin film of clean oil to lips of new oil seal (25) in spindle (10) bore, bore of bronze bushing (24) in spindle and

oil seal journal on axle shaft short end.

CAUTION

Inner oil seal and bushing in bore of spindle could be damaged when sliding spindle past axle splines. Install

spindle carefully to avoid damaging bushing inner oil seal. Failure to do so could cause premature compo-

nent failure.

4.

Install spindle (10).

NOTE

Install two shorter capscrews at two top holes and two capscrews at bottom two holes.

5.

Install ten capscrews (21), four shorter capscrews (22) and fourteen flatwashers (23) to secure wheel bearing spindle

(10). Torque capscrews to 150 lb-ft (203 Nm).

0244 00-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |