|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

ENGINE OIL PUMP MAINTENANCE - CONTINUED

0221 00

REMOVAL - CONTINUED

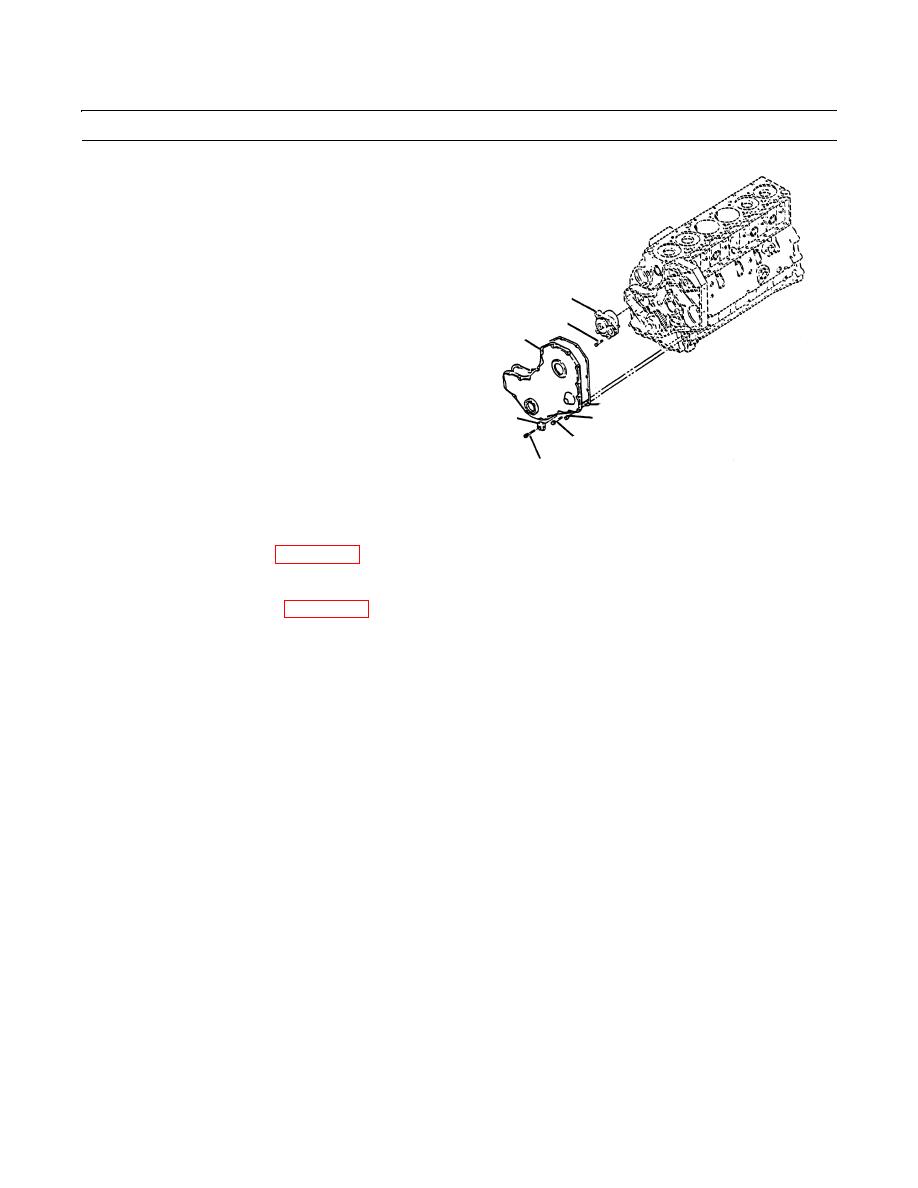

NOTE

Capscrews which retain timing gear cover

are of three sizes. Note size and location of

capscrews before removal to allow correct

16

location at assembly.

15

9

6.

Remove capscrew (10) and belt guide (11).

7.

Remove eleven capscrews (12) and eight capscrews

(13).

14

8.

Remove timing gear cover (9) and gasket (14). Dis-

11

12

card gasket.

13

9.

Remove four capscrews (15).

409-1039

10

10.

Remove oil pump (16).

CLEANING

See Cleaning instructions (WP 0316 00).

INSPECTION

See Inspection instructions (WP 0317 00).

INSTALLATION

CAUTION

When installing oil pump, be sure idler gear pin is installed in the locating bore in the cylinder block. Failure

to properly locate oil pump can result in damage to pump and to cylinder block bore.

NOTE

Filling oil pump with oil prior to installation will help to prime pump at engine start-up.

Back plate on pump seats against bottom of cylinder block bore. When pump is correctly installed, flange on

pump will not touch cylinder block.

1.

Install oil pump (16) into cylinder block bore and secure with four capscrews (15).

2.

Torque capscrews (15) in opposite pairs to 6 lb-ft (8 Nm).

CAUTION

Lips of seal in cover and seal surface on crankshaft end must be clean and free of oil. Failure to properly

clean sealing surfaces may cause oil to leak at seal.

When installing timing gear cover, be careful not to damage lips of seal. Failure to protect seal lips during

installation of seal over crankshaft end may damage oil seal lips and cause oil leakage.

3.

Install pilot tool from seal kit inside diameter of seal to protect seal lips during gear cover (9) installation.

4.

Install new gasket (14) and timing gear cover (9) onto engine block.

5.

Remove pilot tool from seal bore.

0221 00-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |