| |

TM10-3930-660-20

18-7.

MLRS ATTACHMENT CONTROL VALVE ASSEMBLY - REPLACE (Cont’ d)

4.

5.

6.

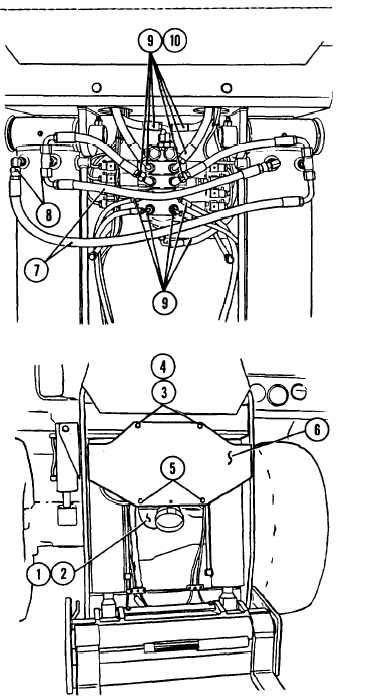

a. Connect eight electrical connectors

(12) as tagged.

b. Tighten eight connector retaining

screws (11) to secure electrical

connectors (12).

CONNECT HYDRAULIC HOSES TO VALVE AND

FRAME TILT CYLINDERS AS TAGGED.

a. Connect eleven hydraulic hoses (9)

to valve fittings (10) as tagged.

b. Connect two crossover hoses (7) to

carriage tilt cylinder fittings (8)

as tagged.

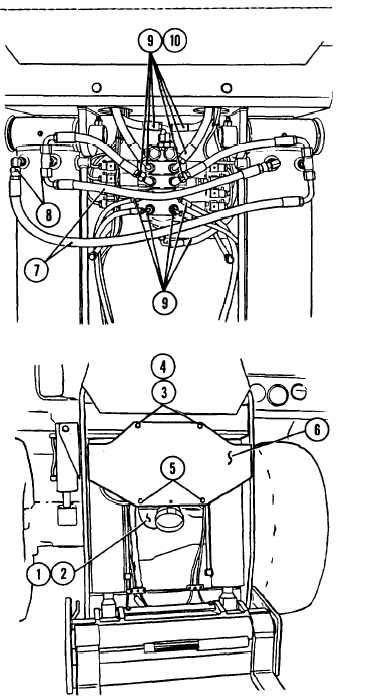

SECURE VALVE COVER.

a.

b.

c.

Position cover (6) over valve and

align mounting holes.

Apply Loctite 242 to two capscrews

(3) and two nuts (5).

Secure cover (6) with two nuts (5),

two capscrews (3), and two

lockwashers (4).

CONNECT FLOODLIGHT ELECTRICAL LEADS

(1) AND (2) AS TAGGED.

White lead of floodlight connects to

lead 71 of vehicle wiring harness. Black

lead of floodlight connects to lead 02

of vehicle wiring harness.

7. CONNECT NEGATIVE BATTELRY CABLE,

PARA. 8-44.

8. PURGE AIR FROM HYDRAULIC SYSTEM BY

CYCLING EACH MLRS ATTACHMENT FUNCTION

FIVE TIMES, TM10-3930-660-10.

Excessive air in hydraulic system may

temporarily prevent MLRS attachment

functions from operating. Attempt to

operate MLRS attachment functions as

required until each function operates

smoothly and completely.

18-33

|