| |

TM10-3930-660-20

13-4.

TIREs- REPLACE (Cont’d)

i.

j.

k.

1.

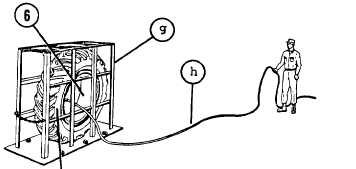

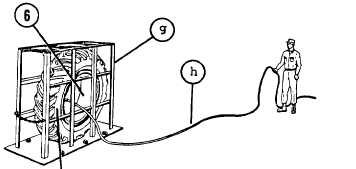

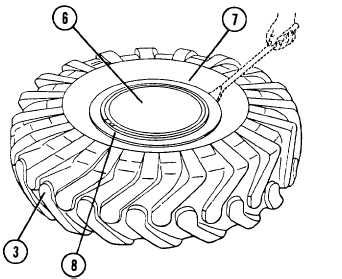

Place wheel assembly (6) and tire

(3) in inflation safety cage (g).

Remove cap (4) from reducer (5).

Using an airhose and gage (h) for

safety cage use, inflate tire (3)

enough to seat both tire beads.

Tire beads should seat before

reaching maximum tire pressure of

45 psi.

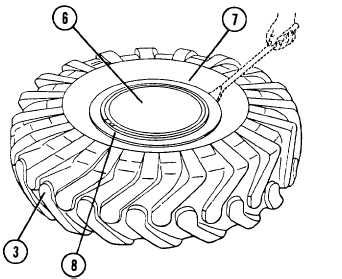

Remove airhose and allow tire to

completely deflate.

Visually

inspect tire beads, aligning ring

(7), and lock ring (8) to see that

they are properly seated.

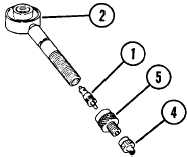

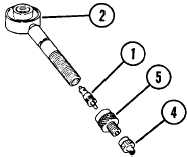

3. INSTALL VALVE CORE (1) TO VALVE STEM

(2) AND INFLATE TIRE (3) TO PROPER

PRESSURE .

a.

b.

Remove reducer (5) from valve

stem (2).

Install valve core (1) into valve

stem (2) with valve core

extractor.

Inflate tires for

Inflate tires for

front axle to 45 psi.

rear axle to 40 psi.

c. Inflate tire (3) to normal

operating pressure and visually

inspect tire beads, aligning ring

(7), and lock ring (8) to see that

they are properly seated.

d. Install cap (4) onto reducer (5)

finger tight and remove wheel

assembly (6) from inflation .

safety cage (g).

5. INSTALL WHEEL ASSEMBLY TO VEHICLE,

PARA. 13-3.

13-10

|