| |

TM10-3930-660-10

Section Ill. Operator Maintenance Procedures

Alphabetical Index of Section III.

Procedure

Service engine oil sampling valve

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Service transmission oil sampling valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Service hydraulic oil sampling valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Service air cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Service radiator

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Service water separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Service parking brake lever

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Service fuel/hydraulic tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3-4.

INTRODUCTION.

Paragraph No.

P a g e N o .

3-6

-

3-7

3-8

3-9

3-12

3-13

3-13

3-14

This section contains maintenance procedures which are the responsibility of the operator. See

paragraph 2-3, the Preventive Maintenance Chart Services for additional maintenance not covered in

this section. The maintenance procedures in this manual are authorized by the Maintenance Allocation

Chart (refer to TM10-3930-660-20).

3-5.

ENGINE OIL SAMPLING VALVE - SERVICE

This task covers:

Obtaining an engine oil sample for the Army Oil Analysis Program (AOAP).

1.

2.

3.

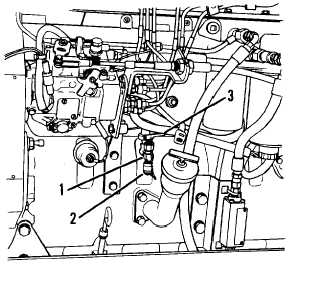

CLEAN THE ENGINE OIL SAMPLING

VALVE (1).

START THE ENGINE, PARAGRAPH 2-6.

BRING IT TO NORMAL OPERATING

TEMPERATURE.

OBTAIN THE OIL SAMPLE.

a. With the engine at idle, remove the dust

cap (2) on the oil sampling valve (1).

b. Attach an appropriate size hose to the

valve, if desired.

3-6

|