| |

TM 10-3930-659-34

5-4.

ENGINE MAIN BEARINGS, THRUST BEARING, AND CRANKSHAFT

REPLACEMENT (Con’t).

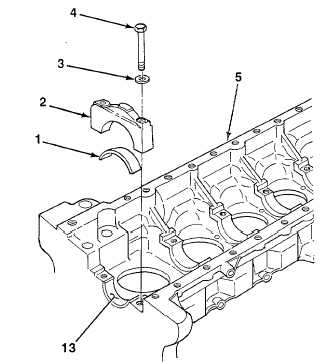

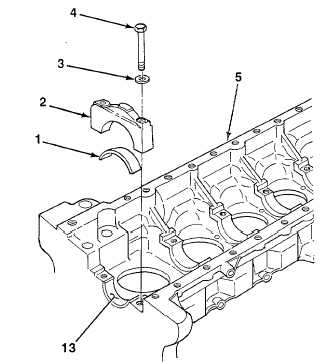

11.

Position lower main bearing (1) on main bearing

cap (2). Ensure that tang on lower main bearing

fits in locking groove on main bearing cap.

CAUTION

Main bearing caps and thrust bearing

cap must be installed in correct

numbered

location

with

indicator

arrow facing camshaft side of engine

block.

12.

Position main bearing cap (2) on engine block

(5). Ensure that tangs on bearings fit in locking

grooves on engine block.

13.

Apply lubricating oil (Item 39, Appendix B) to

threads of two screws (4). Install two washers (3)

and screws on main bearing cap (2) and engine

block (5). Torque screws to 85 Ib.-ft. (115 N•m).

14.

Using inside caliper micrometer, measure and

note inside diameter of lower and upper main

bearings (1 and 13). Diameter must be 3.125-

3.127 in. (7.9387.943 cm).

15.

Subtract largest crankshaft main bearing journal measurement taken in step 7 from measurement taken in step

14. Difference between the two measurements is clearance. Maximum clearance allowable is 0.006 in. (0.152 mm).

NOTE

If one main or thrust bearing is replaced, all main and thrust bearings must be replaced.

16.

If clearance is not within specification and mating main bearing journal is within specification, replace crankshaft

and bearings.

17.

Remove two screws (4), washers (3), and main bearing cap (2) from engine block (5). Remove lower main

bearing (1) from main bearing cap.

18.

Remove upper main bearing (13) from engine block (5).

19.

Repeat steps 10 through 18 for remaining main bearings and thrust bearing.

20.

If end play measurement taken in step 1 of subparagraph a is not within specification, replace crankshaft.

TA708152

5-40

|