| |

TM 10-3930-659-34

5-3.

PISTON, CONNECTING ROD, AND CONNECTING ROD BEARING MAINTENANCE (Con’t).

WARNING

Dry cleaning solvent, P-D-680, is toxic and flammable. Always wear protective

goggles and gloves, and use only in a well-ventilated area. Avoid contact with skin,

eyes, and clothes, and DO NOT breathe vapors. DO NOT use near open flame or

excessive heat. The solvent's flash point is 100°F-138°F (380C-59°C). If you become

dizzy while using cleaning solvent, immediately get fresh air and medical help. If

solvent contacts eyes, immediately wash your eyes and get medical aid.

3.

Using nonelectrical wire, clean oil holes and flush clean with dry cleaning solvent. Dry thoroughly with clean rags.

4.

Clean connecting rod, piston pin, and piston pin bushing with dry cleaning solvent, and dry thoroughly with clean

rags.

5.

Inspect upper and lower main bearings for cracks, grooves, rough spots, scratches, and breaks. Remove rough

spots and minor scratches with crocus cloth. Replace upper and lower main bearings if otherwise damaged.

6.

Inspect piston for cracks, scoring, and excessive wear or scorching. Replace piston if badly scored.

7.

Using ring groove wear gage, measure compression ring groove. If shoulders of gage touch ring land, groove is

excessively worn and piston must be replaced.

NOTE

Piston rings come in a kit. If one piston ring requires replacement, all piston rings (compression

ring, oil control ring, and oil ring expander) must be replaced.

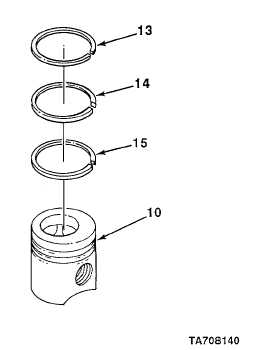

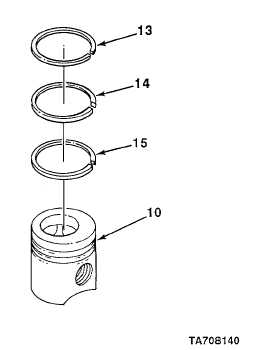

8.

Using

piston

ring

expander,

install

new

compression ring (13), new oil control ring (14),

and new oil ring expander (15) on piston (10).

9.

Using feeler gage, measure compression ring

(13) clearance. Clearance must not exceed

0.008 in. (0.203 mm).

10.

Using

piston

ring

expander,

remove

compression ring (13), oil control ring (14), and

oil expander ring (15) from piston (10).

5-27

|