| |

TM 10-3930-659-34

5-2.

CYLINDER LINERS MAINTENANCE (Con’t).

13.Remove piston (8) from cylinder liner (4) and insert

piston upside down in cylinder liner. Position

piston 1 in. (25.4 mm) below top of cylinder

liner.

14.Using feeler gage, measure and note clearance

between piston (8) and cylinder liner (4).

Clearance must be 0.003-0.006 in. (0.076-

0.152 mm).

15.Difference between measurements in steps 12 and

14 is cylinder liner taper. Cylinder liner taper

must not exceed 0.002 in. (0.051 mm).

16.Remove piston (8) from cylinder liner (4).

NOTE

Perform steps 17 through 19 only if further inspection is required.

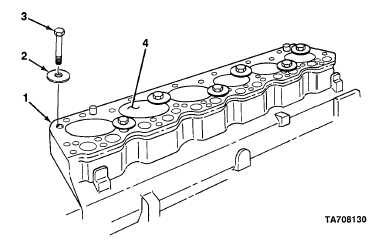

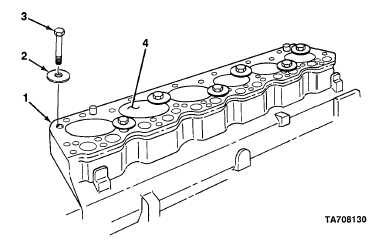

17.

Remove seven screws (3) and washers (2) from engine block (1).

18.

Remove cylinder liners (see subparagraph c).

19.

Inspect outer surface of cylinder liners (4) for pitting and corrosion. Using nonelectrical wire and rule, measure

depth of pitting or corrosion. Depth must not exceed one-half the wall thickness of cylinder liner. If depth exceeds

specification, replace cylinder liner (see subparagraph c).

5-16

|