| |

TM 10-3930-659-34

5-2.

CYLINDER LINERS MAINTENANCE (Con’t).

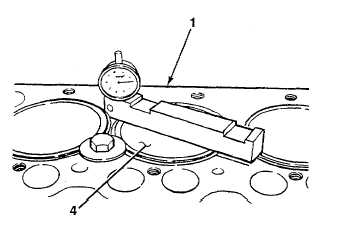

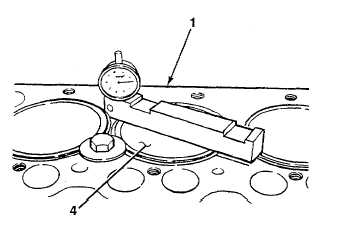

7.

Using dial indicator and depth gage micrometer,

measure and note height of cylinder liner (4)

from engine (1). Measurement must be 0.0004-

0.0040 in. (0.0102-0.1016 mm). Repeat step

for

remaining

cylinder

liners.

Differences

between measurements must not exceed 0.002

in. (0.051 mm).

8.

Remove six pistons and connecting rods (see

paragraph 5-3).

9.

Inspect cylinder liners (4) for cracks, scoring,

glazing, discoloration, and abnormal wear. If

damaged,

replace

cylinder

liners

(see

subparagraph c).

NOTE

Perform steps 10 through 16 for all six pistons and cylinder liners.

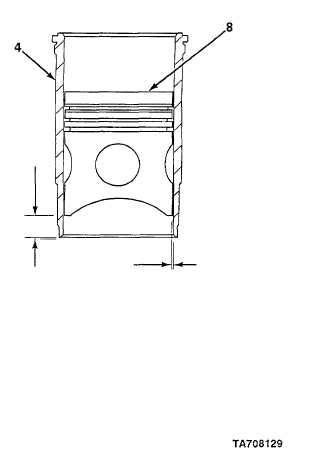

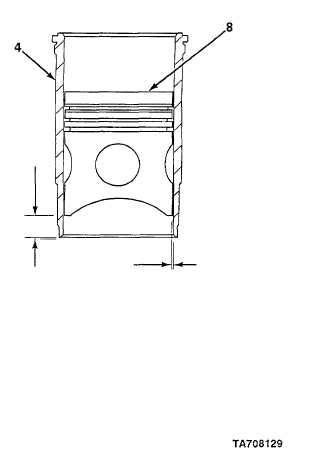

10.

Insert piston (8) into same cylinder liner (4) as

removed, and ensure that front markings of

piston and cylinder liner are alined. Position

piston so bottom edge is 1 in. (25.4 mm) from

bottom of cylinder liner.

11.

Using feeler gage, measure and note clearance

between piston (8) and cylinder liner (4) at a

point 900 from piston pin bore.

12.

Rotate piston (8) 900 and repeat step 11.

Difference between measurements in steps 11

and 12 is amount cylinder liner (4) is out-of-

round. Maximum allowable out-of-round is 0.002

in. (0.051 mm).

5-15

|