| |

TM 10-3930-659-34

5-1.

ENGINE BLOCK MAINTENANCE (Con’t).

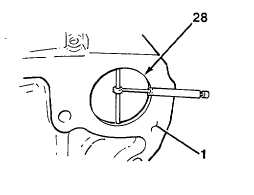

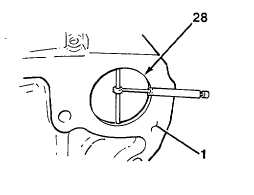

29.

Using inside caliper micrometer, measure inside

diameter of camshaft bore (28). Measurement

must be 2.204-2.205 in. (5.598-5.601 cm). If

measurement is greater than

specification,

replace engine block (1).

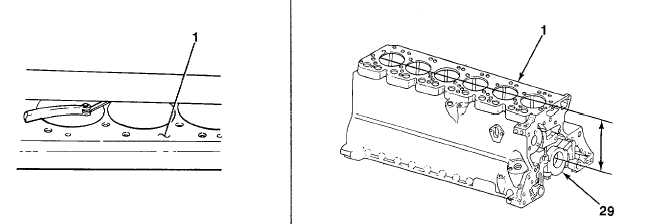

30.

Using machinist’s steel rule and feeler gage, measure flatness of engine block (1). Maximum allowable flatness

variation is 0.003 in. (0.076 mm). If measurement is greater than specification, replace engine block.

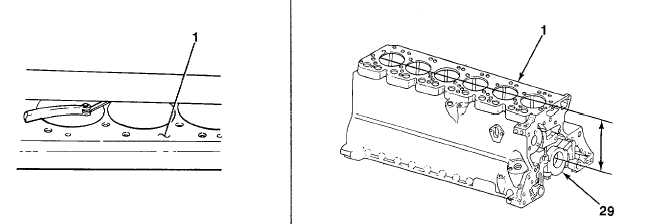

31.

Measure from top of engine block (1) to centerline of crankshaft bearing (29). Minimum allowable measurement is

11.889 in. (30.198 cm). If measurement is less than specification, replace engine block.

c.

REPAIR

1.

Repair damaged threads using die and tap threading set.

2.

Remove high spots or burrs on gasket surfaces with a sharpening stone.

5-10

|