| |

TM 10-3930-659-34

4-6.

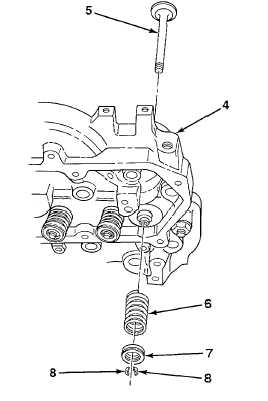

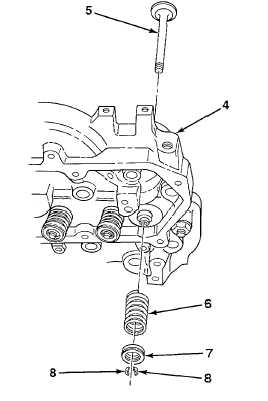

CYLINDER HEAD ASSEMBLY REPAIR (Con’t).

3.

Using valve spring lifter, compress valve spring

(6) and remove valve spring retaining lock (8)

from cylinder head valve (5).

CAUTION

Use care not to nick or scratch surface between cylinder

head valve face and stem. A small nick or scratch can

cause cylinder head valve to break during operation.

NOTE

Note position of cylinder head valves in cylinder head to

aid during installation. Cylinder head valves must be

installed in same position to prevent damage to parts.

4.

Slowly release tension from valve spring lifter

and remove rotator (7), valve spring (6), and

cylinder head valve (5) from cylinder head (4).

5.

Repeat steps 3 and 4 for remaining cylinder

head valves.

b.

CLEANING AND INSPECTION

WARNING

• Carbon removing compound is a corrosive liquid. If splashed in eyes, it can cause blindness. If splashed

on skin, it can cause serious burns. Always wear protective goggles or lenses, rubber apron, and rubber

gloves. If accidently splashed in eyes or on skin, flush with clean, cool water. Refer to FM 21-1 1 for first

aid information and seek medical attention immediately.

• Compressed air used for cleaning or drying purposes, or for clearing restrictions, should never exceed

30 psi (207 kPa). Wear protective clothing (goggles/shield, gloves, etc.) and use caution to avoid injury

to personnel.

1. Soak cylinder head and cylinder head valves overnight in carbon removing compound. Using wire brush and hot

water, clean all carbon deposits from cylinder head and cylinder head valves. Dry thoroughly with compressed air.

2. Inspect cylinder head for cracks, breaks, warping, and abnormal wear. Replace cylinder head if damaged.

TA708067

4-21

|