| |

TM 10-3930-659-20

2-21.

ELECTRICAL GROUND POINTS (Con't).

(4)

Look for cracks, loose terminal lugs, and stripped threads. Replace any defective parts.

(5)

Install hardware connecting ground cable terminal lug to ground point. Ensure that all hardware is tight.

2-22.

LINES AND PORTS.

To keep dirt from contaminating fluid systems when removing and installing hydraulic, fuel, oil, and coolant lines,

perform the following steps:

(1)

Clean fittings and surrounding area before disconnecting lines.

(2)

Cover, cap, plug, or tape lines and ports after disconnecting lines. When these are not available, use

hand-carved wooden plugs, clean rags (Item 27, Appendix C), duct tape (Item 35, Appendix C), or other similar materials

to prevent dirt from entering system.

(3)

Ensure that new and used parts are clean before installing.

(4)

Wait to remove cover, cap, plug, or tape from lines and ports until just before installing lines.

2-23.

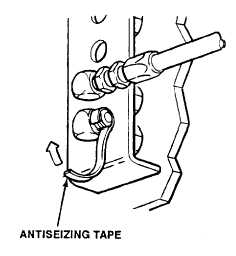

ANTISEIZING TAPE.

When connecting hydraulic, fuel, and oil lines and fittings without compression sleeves or packings, antiseizing

tape (Item 34, Appendix C) may be used to keep connections from leaking. Use as follows:

(1)

Ensure that threads are clean and dry.

(2)

Start antiseizing tape one or two

threads from small or leading edge of fitting, joining tape

together with an overlap of about X in. (3.18 mm) for fit-

tings with fine threads. For fittings with coarse threads,

tape should be wrapped around threads two or three

times.

(3)

Tightly wrap antiseizing tape in same

direction as you would tighten a nut. Tape must be

pressed into threads without cutting or ripping.

CAUTION

DO NOT exceed specified torque or use

power tools to tighten fittings taped with

antiseizing tape. Overtightening could

damage

fitting

threads

and

cause

connection to leak. (4) Using hand tools,

tighten fittings to specified torque.

TA706717

2-12

|