| |

TM 10-3930-653-14&P

(3) Install piston with "F" mark (on piston head) to front.

(4) Set crankshaft pins to top and bottom dead center

position.

(5) Position piston rings so that end gaps are offset

(alternately for adjacent rings) by 180° and so that none

of the end gaps are aligned in piston thrust direction.

(6) Install piston and connecting rod assembly (without

cap) from top.

(7) Install cap on each assembly before Installing the

next piston and connecting rod assembly.

(8) INSTALLING CONNECTING ROD CAPS

Install the connecting rod cap so that the cap and

connecting rod cylinder number markings are aligned (on

the same side).

Turn crankshaft one revolution before installing the

next piston and rod.

Connecting rod caps

5.0 to 6.0 kg-m

(36 to 43 ft-lb)

Fig. 4-87. Tightening Connecting Rod Bearing Caps .

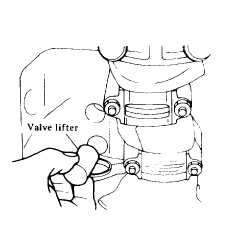

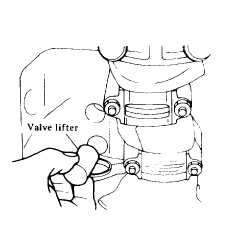

(9) INSTALLING VALVE LIFTERS

Make sure that the valve lifters are installed in proper

direction. Apply oil to the holes in the cylinder block and

lightly press the valve lifters into the holes by hand.

Apply Loc-TiteÒ and install the front plate and packing.

Fig. 4-88. Insert Valve Lifter.

(10) INSTALLING CAMSHAFT

(1) Install the camshaft in place, taking care not to

damage the bearing bushings.

(2) Tighten the bolts attaching the camshaft locating

plate to the cylinder block to the specified torque.

Tightening torque:

Camshaft locating plate to

cylinder block bolts

0.6 to 0.8 kg-m

(4.3 to 5.8 ft-lb)

Temporarily install the camshaft and crank shaft

sprockets in place, and adjust the position of both gears.

using washers. so that they are in line within 0.2 mm

(0.008 in). Align the marks on the gears and timing

chain, and install them to the engine and tighten the

camshaft gear securing nut

Tightening torque:

Camshaft gear securing nut

4.5 to 6.0 kg-m

(33 to 43 ft-lb)

4-46

|