| |

TM 10-3930-653-14&P

(5) INSTALLING CRANKSHAFT

Install the crankshaft bearing caps with spring washers

and bolts. and tighten the bolts

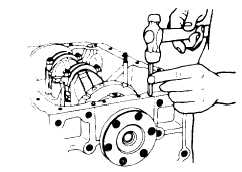

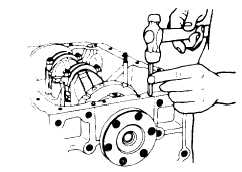

(1) Install seals on both sides of rear crankshaft bearing

cap. Face wire backed (hard) side of seal toward cap.

Fig. 4-83. Installing Rear Bearing Side Seals.

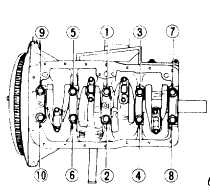

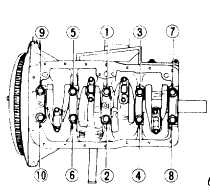

Fig. 4-84. Torque Sequence of Main Bearing Cap Bolts.

(2) Install front and rear caps with their arrow marks to

front.

(3) Move crankshaft in an axial (shaft) direction so that

center bearing cap is properly aligned and then tighten

crankshaft bearing caps to prescribed tightening torque.

(4) Do not tighten caps all at once Tighten them in 3 or 4

stages beginning from inside to out (repeating tightening

sequence 3 or 4 times until completely tightened to

prescribed tightening torque).

(5) While tightening caps, check crankshaft to make

sure that it turns freely.

Cranking ( crankshaft turning) torque should be 2.0

kg-m (14 ft-lb) or less.

Tightening torque:

Main bearing cap

8.5 to 11 kg-m

(61 to 80 ft-lb)

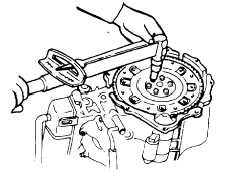

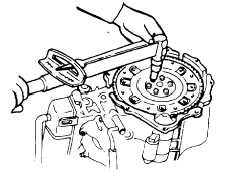

(6) INSTALLING FLYWHEEL

(1) Install flywheel housing.

(2) Install flywheel with bolts and lock plates. and bend

lock plates from outside for safety lock.

Fig. 4-85. Installing Flywheel.

Tighten crank nuts

Tightening torque:

Flywheel

6.0 to 7.5 kg-m

(43 to 54 ft-lb)

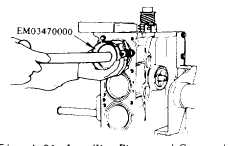

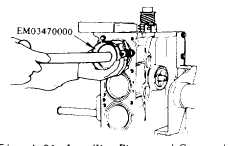

(7) INSTALLING PISTONS

Fig. 4-86. Installing Piston and Connecting

Rod Assembly.

4-45

|