| |

TM 10-3930-653-14&P

(2) INSTALLING VALVE ROCKER SHAFT

Install the bracket and inner spring on the valve

rocker shaft. The shaft has four installation bolt holes.

Face the side with the larger hole (which also serves as

a lubrication hole) to the front. Install the lock washer.

spacer, and cotter pin in that sequence to both ends of

the rocker arms.

(3) INSTALLING CAM BUSHINGS

(1) Installing center bushing

Face notch toward distributor drive side (downward)

match block and jig caulking hole and tap on bushing.

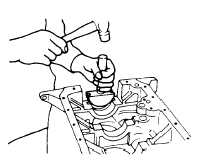

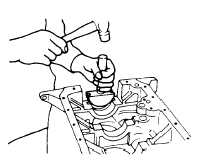

Fig. 4-80. Installing Rear Bushing.

(2) Installing rear bushing

Face arrow mark on end of bushing, upward.

Align oil hole with oil hole in cylinder block and tap rear

bushing into position, as shown in figure 2-68. Diameter

of bushing is slightly larger toward rear and bushing is

press fit in block.

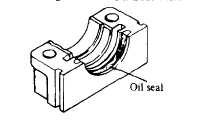

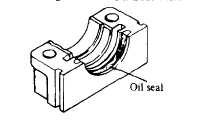

(4) CRANKSHAFT REAR BEARING OIL SEAL

(1) Using oil seal replacer, install rear oil seals into

cylinder block groove and rear bearing cap respectively.

When seal is fully inserted, ends of seal protruding

above bearing supports should be cut off so that seal

ends line up with each other.

Fig. 4-81. Oil Seal Installation.

Fig. 4-82. Oil Seal Installation.

(2) Install main bearings and thrust bushings in main

bearing caps and cylinder block.

WARNING

Dry, cleaning solvent P-D 680 is toxic

and flammable. protective goggles

and

gloves

and

use

only

in

a

ventilated area. Avoid contact with

skin, eyes, and clothes and don’t

breathe vapors. Do not use near

open flame or excessive heat. If you

become dizzy while cleaning with

solvent, get fresh air immediately!

and get medical aid. If contact with

skin or clothing is made, flush with

water. If contact, with eyes is made,

flush your eyes with water and get

medical aid immediately.

WARNING

Compressed air used for cleaning

purposes not exceed 30 PSI. Use

only with effective chip guarding and

personal

protective

equipment

(goggles, shield, gloves, etc.).

(3) Thoroughly clean reverse side of upper and lower

bearing shells and make sure that notch and tang on

bearing shells are properly matched.

4-44

|