| |

TM 10-3930-653-14&P

Inspect the push rods. If excessively worn, twisted,

or damaged, replace with a new push rod. If bent by

more than 0.05 mm (0.0020 in), correct or replace.

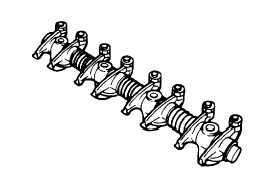

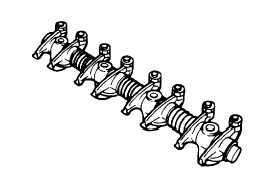

(2) ROCKER SHAFT

Inspect the rocker shaft for wear, damage, bending,

etc. Replace if worn by more than 0.05 mm (0.0020 in).

(3) ROCKER ARM AND

ADJUSTING BOLT

Inspect the portion of the rocker arm and adjusting

bolt contacting the valve stem and check for fit with the

rocker shaft. If excessively worn or scarred, or if rocker

shaft clearance exceeds the prescribed limit, replace

the rocker arm (and adjusting bolt) with a new one.

Fig. 4-73. Valve Rocker Shaft Assembly

Correct to within

Service limit

Rocker arm/

0.020 to 0.054

shaft clearan-

(00009 to 0.0021)

0.1 (0.0039)

ce

mm (in)

4-2-4-13.

DRIVING PLATE,

RING GEAR AND

FLYWHEEL

Inspect driving plate disc or flywheel contact surface

and ring gear teeth. If excessively damaged or worn,

repair or replace as required. On flywheel, if ring gear

teeth are only slight-ly worn or damaged, ring gear can

be reused by changing the installation setting to flywheel

by 45°

For replacement, heat the ring gear to 1800C

(356°F) and install by shrinkage-fitting.

(1) MEASURING WOBBLE

Measure wobble with a dial gauge while turning

crankshaft. If it exceeds specified limits, replace parts.

(1) Flywheel

Wobble limit:

A:

Less than 0.1 mm (0.004 in)

Note:

Wobble

limit

A

is

max.

allowable wobbling of flywheel, as

measured

perpendicularly

with

respect to flat surface of flywheel.

Fig. 4-74. Measuring Flywheel

4 - 41

|