| |

TM 10-3930-653-14&P

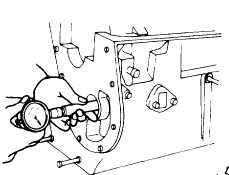

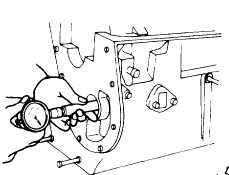

(2) Measuring lubrication

(oil) clearance

Measure the inside diameter of each bushing with a

bore gauge. If lubrication (oil) clearance exceeds the

prescribed limit, replace the bushing.

Fig. 4-69. Measuring Bushing l.D.

Correct to within

Service (clear

ance) limit

Lubrica-

tion (oil)

Front

& rear

0.025 to 0.051

(0.0010 to 0.0020)

0.1(00039)

clearane

Center

0.038 to 0.062

mm (in)

(0.0015 to 0.0024)

0.15 (0.0059)

(6) TIMING SPROCKET

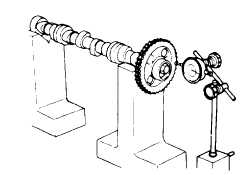

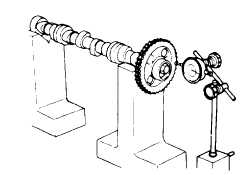

(1) Inspecting cam gear for wobble

With the camshaft and camshaft sprocket placed on

V-blocks. measure camshaft sprocket wobble, and

correct or replace the cam gear if wobble exceeds 0.1

mm (0.0039 in). Also inspect the sprocket for broken or

damaged teeth and for wear or damage on the boss

surface. If excessively worn or damaged, replace with a

new gear.

Fig. 4-70. Checking Camshaft Sprocket Wobble

(7) FRONT COVER AND

HYDRAULIC PUMP

CHAIN COVER

Inspect the installation (mating) surface and oil seal.

If damaged or faulty, correct or replace as required.

4-2-4-12.

VALVE ROCKER

MECHANISM

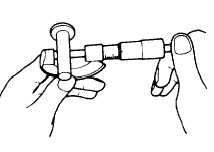

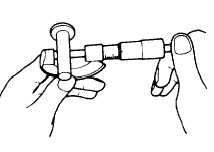

(1) VALVE LIFTERS

Inspect the periphery of the valve lifter and the cam

contact surface. Replace the valve lifter if excessively

worn, damaged or fused. Also check for fit in the

cylinder block and replace if fit is not proper. Fit should

be such that the lifter, with oil applied, lowers slowly and

naturally In the hole in the cylinder block.

Fig. 4-71. Measuring Diameter of Valve Lifter

Correct to

Service limit

within

Fit (clearance) of

valve lifter and

0.016 to 0.052

0.1 (0.0039)

cylinder block

(0.0006 to 0.0020)

hole

mm (in)

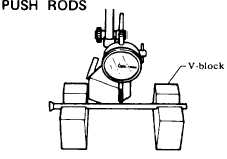

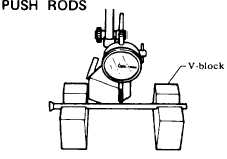

Fig. 4-72. Measuring Push Rod Bending

4 - 40

|