| |

TM 10-3930-653-14&P

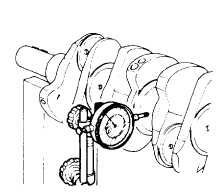

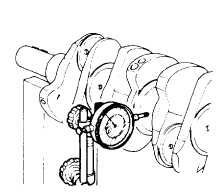

(3) MEASURING CRANKSHAFT

FOR BENDING

Support both end journals in a V-block or other

appropriate support, apply a dial gauge to the center of

the journal bearing surface, turn the crankshaft and

measure the bend of the crankshaft (I’ of the maximum

valve shown on the gauge is the amount of bend) If bent

beyond the prescribed service limit, straighten with a

press, or replace the crankshaft, as required.

Fig. 4-62. Measuring Crankshaft for Bending

Correct to within

Service (bend)

mm (in)

limit mm (in)

Crankshaft

0.02 (0.0008)

0.05 (0.0020)

bend

Note: When measuring bend, use a

dial gauge. Bend value is half of the

reading obtained when crankshaft is

turned one full revolution with a dial

gauge attached to its center journal.

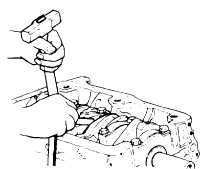

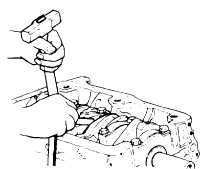

(4) MEASURING END PLAY

With the crankshaft installed in place and the bearing

caps tightened. check the end play with the bearing

caps tightened, check the end play at the center bearing.

If the clearance exceeds the limit. replace the center

bearing with a new one.

Fig. 4-63. Checking End Play

Standard

Limit

End play

0.05 to 0.18

0.2 (0.0079)

mm (in)

(0.0020 to 0.0071)

4-2-4-10.

BEARING

SHELLS

(1) NSPECTING BEARING

SURFACES

The upper and lower bearing are matched for the

front, rear and center bearings and should not be

interchanged (mixed). (The upper bearing shell for the

rear bearing, for example, should not be used with the

lower bearing shell for the front bearing). Make sure that

the bearings are not scarred or scratched (due to entry of

dirt or other abrasive matter) and that there is no sign of

metal fatigue, peeling, or binding. Replace both upper

and

lower

bearing

shells

as

a

set,

if

faulty.

4 - 37

|