| |

TM 10-3930-653-14&P

(2) CONNECTING ROD WEIGHT

When replacing any or all of the connecting rods,

carefully measure their weight to insure that the

difference in weight between individual connecting rods

does not exceed 5 gr (0.18 oz).

Difference in weight between

individual connecting rods

(including metal fasteners):

Within 5 gr (0.18 oz)

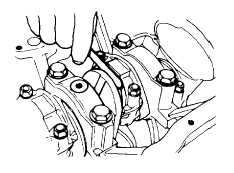

(3) MEASURING CONNECTING

ROD END PLAY

Apply the bushing to the connecting rods and install

them on the crankshaft. By pushing the rod to one side,

and using a feeler (thickness) gauge, measure rod

clearance in the shaft (axial) direction against the

crankpin.

Fig. 4-57. Measuring Connecting Rod

Standard

Limit

End play

0.17 to 0.3 (0.0067 to

04 (0.0157)

mm (in)

0.0118)

(4) CONNECTING ROD BUSHINGS

(1) Inspect bushings for binding, fusing, peeling,

contact, etc., and replace if faulty.

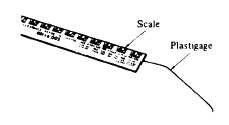

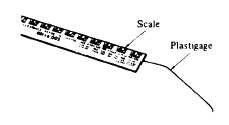

(2) Measure lubrication (oil) clearance with a width

gauge (plastigage).

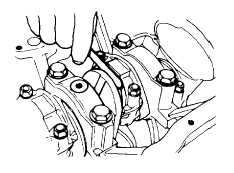

(5) Measuring lubrication

(oil) clearance

(1) Thoroughly clean

all

oil

and

dirt

from

each

component (especially reverse side of bushing) and

install connecting rod bushings.

Fig. 4-58. Plastigage

(2) Cut a width gauge (plastigage) the same width as

the bushing and provide oil clearance parallel to crank

pin. After installing connecting rods, tighten to specified

torque.

Tightening torque:

Connecting rod

10 to 11 kg-m

(72 to 80 ft-lb)

CAUTION:

Do

not

turn

crankshaft

while

plastigage is being inserted.

Fig. 4-59. Measuring Lubrication {(Oil)

Clearance (II)

4 - 35

|