| |

TM 10-3930-653-14&P

Prescribed clear-

0.025 to 0.045

ance

(0.0010 to 0.0018)

mm (in)

[20°C (68°F)]

Feeler gauge

pulling force

0.5 to 1.5

kg (lb)

(1.1 to 3.3)

Feeler gauge

thickness

0.04 (0.0016)

mm (in)

(6) Cylinder liner

If cylinder bore exceeds standard size by more than

1.5 mm (0.059 in), apply a cylinder liner. Use a standard

size piston and hone for proper fit.

Measure outside diameter of liner (at top, middle and

bottom) and hone cylinder bore for fit [oversize of 0.005

to 0.085 mm (0.0002 to 0.0033 in)] based upon

maximum measure-ment value. Liners are removed in

direction of cylinder head. When difficult to remove,

remove with a press.

Outer diameter

Inner diameter

Size Mark

mm (in)

mm (in)

40

91.20 to 91.25

(3.5905 to 3.5925)

45

91.70 to 91.75

86.70 to 86.80

(3.6102 to 3.6122)

(3.413 to 3.417)

50

92.20 to 92.25

(3.6299 to 3.6319)

4-2-4-7.

PISTON, PISTON PIN,

AND PISTON RINGS

(1) MEASURING PISTON WEAR

(1) Inspect piston thrust surface for binding, scratches,

or scars, and replace if excessively damaged or faulty.

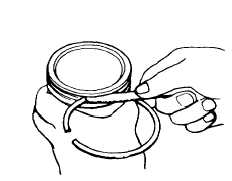

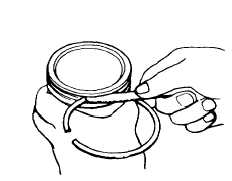

Fig. 4-51. Checking Ring Grooves

(2) Measure

piston

ring

to

piston

groove

(land)

clearance. For this measurement, install a new ring on

piston and measure with a feeler (thickness) gauge. If

clearance exceeds pres-cribed limits, replace rings (or

piston) as required.

Standard mm (in)

Limit mm (in)

Piston

Top

0.040 to 0.073

ring-to-

(0.0016 to 0.0029)

0.1(0.0039)

groove

Second

0.030 to 0.063

(land)

(0.0012 to 0.0025)

0.1 (0.0039)

clear-

Oil

0.03 to 0.08

ance-

(0.0012 to 0.0031)

0.2 (0.0079)

(3) Difference in weight between piston assemblies for

individual cylinders should be within 2 grams (0.0705 oz).

(2) PISTON RINGS

(1) Piston ring end gap

To measure piston ring end gap, apply piston ring to

part of piston skirt where cylinder wear is minimum,

invert piston and, after assuring that piston and ring are

positioned at right angles to cylinder, depress piston.

Measure piston ring end gap with a thickness gauge

and replace piston ring with a new ring if end gap

measurement exceeds I mm (0.0394 in). If end gap is

less than 0.15 mm (0.0059 in), either correct by applying

an oil stone to grind down ends of ring, or replace ring

with a new ring.

(2) Measuring piston ring contracting force.

Measure contracting force with a ring tester. If load

required to contact gap is below specified value, replace

ring.

4 - 32

|