| |

TM 10-3930-653-1 4&P

4-2-4-6.

CYLINDER BLOCK

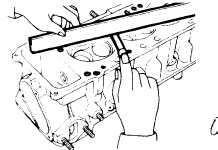

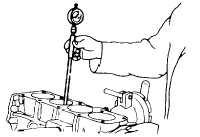

Measuring longitudinal and transverse warp of

cylinder block surface.

Fig. 4-48. Measuring Warp of

Cylinder Block

(1) Remove carbon and other material adherring to

cylinder block surface and Inspect for cracks, scars,

damage, etc. and then measure cylinder head (using a

straight edge and feeler gauge) for both longitudinal and

transverse warp.

Correct to

within

Service limit

Longitudinal

0.05

0.10

direction

(0.0020)

(0.0039)

Cylinder

mm (in)

block

surface

Transverse

direction

0.02

0.04

mm (in)

(0.0008)

(0.0016)

(2) Perform a water leakage test using a hydraulic

pressure of from 4 to 4.5 kg/cm2 (57 to 64 psi).

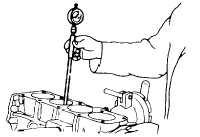

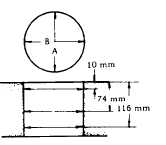

(1) MEASURING CYLINDER

BORE

Measure the cylinder bore and if excessively worn or

tapered or if scarred. pitted or damaged, or if the piston

rings bind, rebore the cylinder. If only slightly worn or

tapered, merely

correct

the

counter-bore

with

a

counterboring tool.

Measure cylinder bore with a cylinder gauge. measuring

in A and B directions at three places from top to bottom.

as shown in the figure, and determine cylinder bore

wear(difference

between

maximum

and

minimum

measurement values).

(difference

between

maximum

and

minimum

measurement values).

Fig. 4-49. Cylinder Bore Measurement

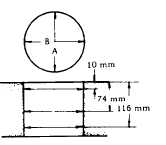

Fig. 4-50. Measuring position of

Cylinder Bore

Correct to

Service

within

(wear) limit

87.20 to

87.25

0.2

Cylinder bore

mm (in)

(3.4331 to

(0.0079)

3.4350)

Cylinder bore out-of-

0.02

-

round limit

mm (in)

(0.0008)

Cylinder bore taper

0.02

-

mm (in)

(0.0008)

Difference in cylinder

0.05

-

bore measurements

mm (in)

4 - 31

|