| |

TM 10-3930-653-14&p

(4) CORRECTING (Grinding)

VALVE SEATS

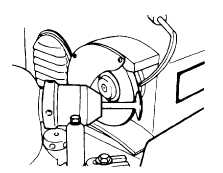

Inspect the valve seat for burning or faulty contact.

When correcting the valve seat, first check the valve

guide for wear, and if excessively worn, replace the valve

and then correct the valve seat.

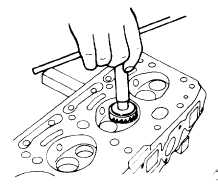

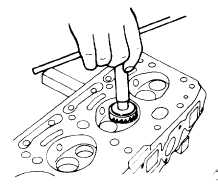

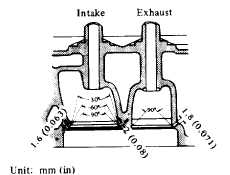

Fig. 4-39. Grinding Valve Seats

(1) Correct valve seat with a seat cutter or seat grinder

and finish for proper fit (proper contact) using grinding

compound.

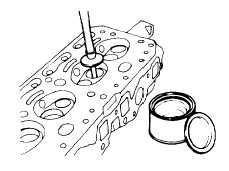

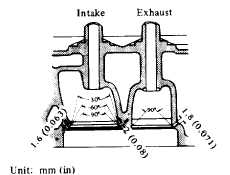

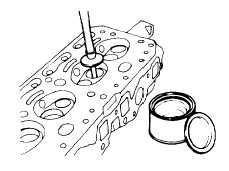

(2) First cut to a 75 angle (around entire valve seat) and

then bevel edge evenly to a 45° angle. For proper fitting.

apply grinding compound (first course and then fine

compound) and work valve back and forth against the

valve seat until a smooth fit is provided, then apply oil for

final fit.

Fig. 4-40. Fitting Valve

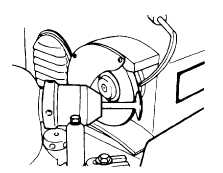

Fig. 4-41. Grinding Valve

Fig. 4-42. Dimensions of Valve Seats

4-2-4-4.

VALVE

(1) Remove all carbon from valve stem and valve seat

and inspect valve stem for wear, binding, etc. and check

valve seat for wear, recession, etc. caused by stem head

wear, and correct or replace as required.

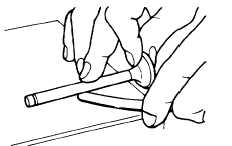

Fig. 4-43. Checking Valve Stem

for Bending

(2) Correct valve seat and valve with a valve grinder.

Replace

valve

if

valve

head

thickness

4 - 29

|