| |

TM 10-3930-653-14&P

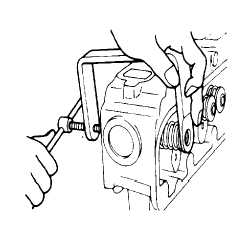

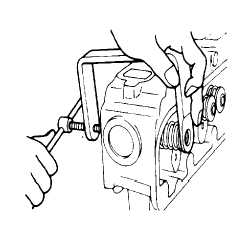

Fig. 4-34. Removing Valve Spring

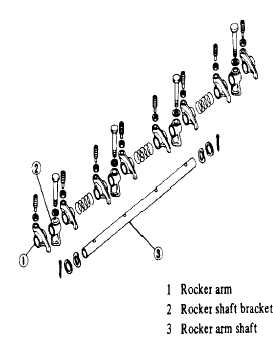

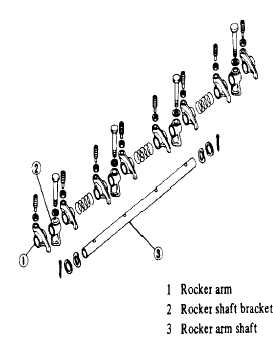

37. Remove bolts from rocker shaft bracket.

38. Remove cotter pin, washer, and outer spring and

then remove rocker arm shaft and bracket in that order.

Fig. 4-35. Disassembling Valve Rocker Parts

39. Remove lock nuts and adjusting nuts from rocker

arm.

WARNING

Exercise care when removing snap

rings, these parts are under spring

tension. Severe injury may result by

the part striking your eye if you don’t

observe this precaution. If your eye

is struck by a foreign object, seek

medical aid immediately.

40. Remove piston rings beginning with top ring (A ring

expander helps but is not mandatory)

41. Extract piston pin.

Piston pin and connecting rod are a press fit. To

remove piston pin, first remove snap rings and heat

piston [80°C (176°F)] and press out pin.

Note: Keep piston, piston pin, piston

rings and connecting rod for each

cylinder together so that they are not

interchanged (mixed) with parts for

other cylinders.

4-2-4.

INSPECTION AND REPAIR

4-2-4-1.

PREPARATIONS FOR

INSPECTION

WARNING

Dry cleaning solvent P-D-680 is toxic

and flammable. Wear protective

goggles and gloves and use only in a

well ventilated area. Avoid contact

with skin, eyes, and clothes and don’t

breathe vapors. Do not use near

open flame or excessive heat. If you

become dizzy while cleaning with

solvent, get fresh air immediately and

get medical aid. If contact with skin

or clothing is made, flush with water.

If contact with eyes is made, wash

your eyes with water and get medical

aid immediately.

WARNING

Compressed air used for cleaning

purposes will not exceed 30 PSI. Use

only with effective chip guarding and

personal

protective

equipment

(goggles/shield, gloves, etc.).

(1) Prior to cleaning, check cylinder head and cylinder

block for water leakage.

(2) Thoroughly clean all compartments and completely

remove all oil, grime, sealing, etc.

(3) Blow compressed air through oil passage in main

gallery, etc. To make sure that passages are not

clogged.

(4) lay out components such as main bearing cap,

connecting rod, etc. as individual assemblies or groups

(for each cylinder) so that they are not interchanged

(mixed).

4-2-4-2.

INTAKE MANIFOLD

WATER JACKET

(1) Check water jacket plate for leakage. If there is

leakage, replace gasket.

(2) Also check water hose for deterioration or damage,

replacing if necessary. If water leaks at or around

connection, retighten clamp.

4 - 27

|