| |

TM 10-3930-653-14&P

4-1-3-3. IGNITION SYSTEM

(1)

CHECKING BATTERY

WARNING

The electrolyte in the battery is a sulfuric acid solution.

Be careful not to drip electrolyte on you or equipment. If

electrolyte spills on you, splash affected areas with water

to flush electrolyte. Get medical attention at once.

CAUTION

Never allow flame or sparks near the battery filler holes.

Explosive hydrogen gas may be present.

Engine must be shut down when filler ports are open.

Check the electrolyte level in each battery

cell.

Permissible value

Fully charged value

(at 20°C, 68°F)

Frigid

Over 1.22

1.28

climates

Tropical

Over 1.18

1.23

climates

Other

Over 1.20

1.26

climates

Clean the top of battery and terminals with a solution

of baking soda. The top of the battery must be clean to

prevent current leakage between terminals and from

positive terminal to hold-down clamp.

In addition to current leakage, prolonged accumulation of

acid and dirt on the top of the battery may cause

corrosion of straps. After tightening terminals, coat them

with

petrolatum

(vaseline)

to

protect

them

from

corrosion.

(1)

Unscrew each filler cap and inspect fluid level. If

the fluid is low. add distilled water to bring the level up

approximately 10 to 20 mm (0.39 to 0.79 in) above the

plates. Do not overfill.

(2)

Measure the specific gravity of battery electrolyte

before adding distilled water.

(2)

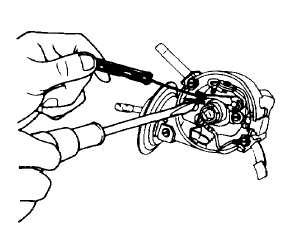

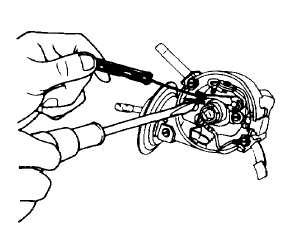

CHECKING DISTRIBUTOR BREAKER POINT

Fig. 4-7. Checking Distributor

Point Gap

Remove distributor cap and inspect points for

excessive

burning

or

pitting.

Replace

points

if

necessary. Use a point file to clean contact area and

remove scale from points. Adjust distributor point gap.

Filing is for cleaning purposes only. Do not attempt to

remove all roughness. Adjust distributor dwell angle on

all engines.

Distributor point gap:

0.45 to 0.55 mm

(0.018 to 0.022 in)

Dwell angle:

49° to 55°

(3)

CHECKING

AND

ADJUSTING

IGNITION

TIMING

With distributor vacuum line disconnected and lift

truck operating at normal idle speed or below, set ignition

timing.

The timing can be observed by the stationary pointer

at front cover and the grooves on crankshaft pulley with a

device called a stroboscopic light (also referred to as a

timing light).

Note that the pulley groove is graduated 5° per scale

division in terms of the crank angle. The top dead center

is located to the extreme left as viewed from the

inspector’s side.

4 - 11

|