| |

TM 10-3930-653-14&P

Adjustment should be made whole engine Is hot. After all

valves have been adjusted correctly, tighten lock nut firmly to

secure the adjustment.

Valve clearance

Intake

0.38 mm

Hot

(0.015 in)

Exhaust

(3)

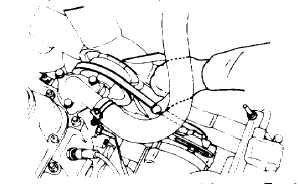

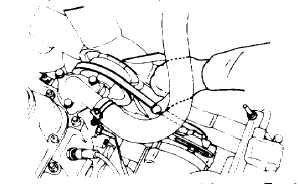

CHECKING AND ADJUSTING FAN BELT

With the engine switched off and the hood up, push the

belt gently downward. You should be able to depress it about

10 mm (1/2 in) midway between fan pulley and alternator

pulley by a force of 10 kg (22 lb). If the fan belt has become

slack through wear, loosen the fixing and adjusting bolts, and

move the alternator away from the engine. Thus will eliminate

the slack. Tighten the bolts again, and make sure that the belt

has been tightened correctly. If tightened excessively it will

wear rapidly and also overload the water pump and alternator

bearings.

Fan belt deflection:

8 to 12 mm

(0.31 to 0.047 in)

Fig. 4-3. Adjusting Pan Belt

Tension.

(4)

CHECKING ENGINE ATTACHING PARTS

Check engine mounting, carburetor, alternator, starter, fuel

pump and distributor for looseness. If necessary, tighten.

Tightening torque:

Engine mounting center

bracket-to-body bolt

7.5 to 9.5 kg-m

(54 to 69 ft-lb)

Engine mounting upper

bracket-to-engine bolt

4.0 to 5.0 kg-m

(29 to 36 ft-lb)

Engine mounting insulator bolt

8.0 to 10.0 kg-m

(58 to 72 ft-lb)

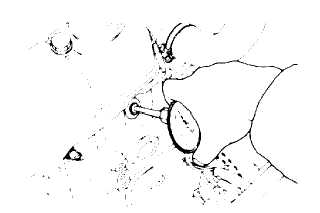

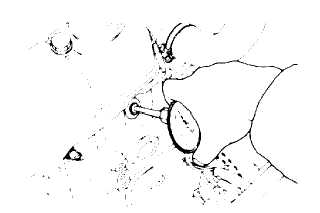

(5)

CHECKING ENGINE COMPRESSION

Note: If this test is to be performed. it should be done

when all plugs are removed for service during basic

tune-up procedure.

Unless check is made for worn rings or for the cause of low

speed, compression check should not be necessary.

Fig. 4-4. Testing Compression

Pressure.

Test compression with engine warm, all spark plugs

removed and throttle and choke opened. No cylinder

compression should be less than 80% of highest cylinder’s.

Excessive variation between cylinders, accompanied by low

speed missing of the cylinder or cylinders which are low,

usually indicates a valve not properly seating or a broken

piston ring. Low pressures, even though uniform, may indicate

worn rings. This may be accompanied by excessive oil

consumption.

Test conclusion

If one or more cylinders read low, inject about one

tablespoon of engine oil on top of the pistons with low reading

cylinders through the spark plug port. Repeat compression

check on these cylinders.

(1)

If compression improves considerably, piston rings

are faulty.

(2)

If compression does not improve, valves are sticking

or not seating properly.

(3)

If two adjacent cylinders indicate low compression

and injecting oil on pistons does not increase compression,

the cause may be a cylinder head gasket leak between the

cylinders.

Engine oil and coolant in cylinder could result from this

problem.

4 - 9

|